Manufacture Cardboard Boxes

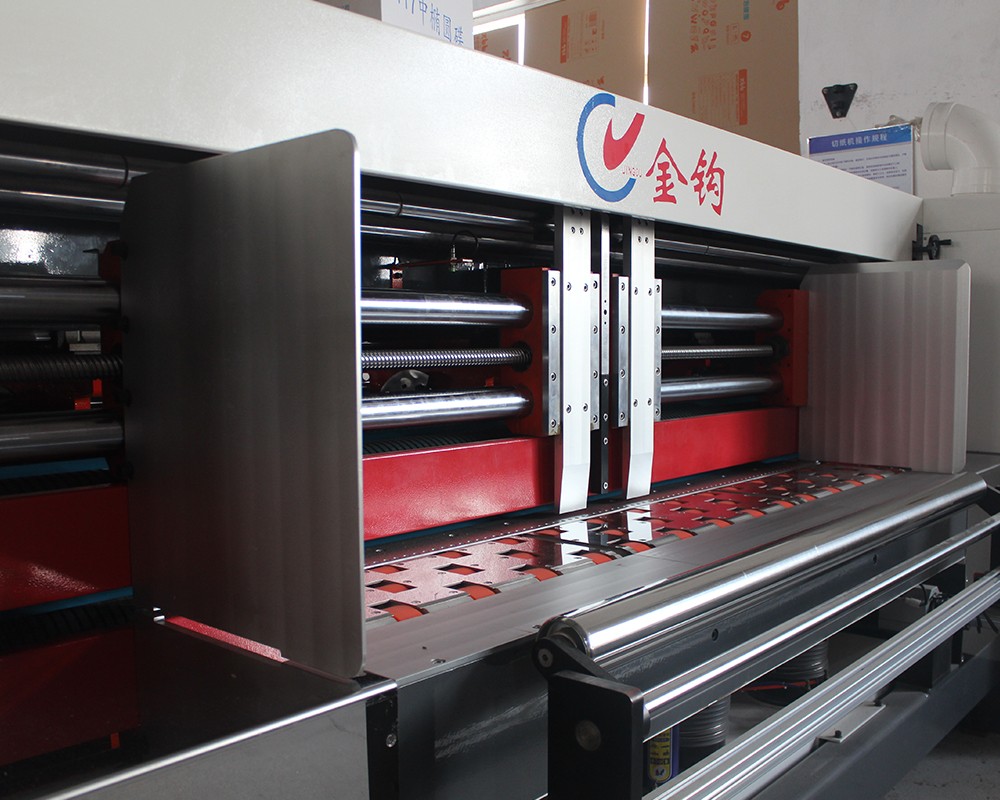

Auto Rotary Slotter Machine

-

+86-13702592807 WhatsApp

-

sales@jingoupack.com Email

Carton manufacturing refers to the process of using materials such as cardboard and corrugated paper to produce cartons of various sizes, shapes and uses through a series of processes and equipment. These cartons are widely used in packaging, logistics, warehousing and other fields to protect goods and facilitate transportation and storage.

Parameter

| Model | RS-25 | UNIT |

| Max.feeding Size | 2500xunlimited | MM |

| Min Cutting Size | 250×600(LxW) | MM |

| Max.slotting Depth | 450 | MM |

| Slotting Width | 7 | MM |

| Feeding Thickness | 2~11 | MM |

| 02omaxbox Height | No Limit | MN |

| 02xo Min Box Height | 120 | MM |

| Min Slotting Gad | 220×60×220×60 | MM |

| Maxanglecutting Width | 45 | MM |

| Total Motorpower | Abt15 | K |

| Dimension(L*W*H) | Abt 1650x4100x1650 | MM |

| Overall Weight | Abt 5200 | KG |

Manufacturing process

Design: Design the size, structure and appearance of the carton according to customer needs and product characteristics. Factors such as the load-bearing capacity, moisture resistance and compression resistance of the carton need to be considered during the design process.

Material preparation: Select suitable cardboard or corrugated paper as raw material. Cardboard is usually made of multiple layers of paper glued together, and has good strength and moisture resistance. Corrugated paper increases the compression resistance of the carton through the corrugated paper layer.

Cutting and forming: Use professional cutting equipment to cut cardboard or corrugated paper into the required size and shape. Then, the cut cardboard or corrugated paper is folded and glued through the molding equipment to form the basic structure of the carton.

Printing and decoration: Print and decorate on the carton as needed. The printed content includes product information, brand logo, barcode, etc. Decorative methods may include hot stamping, lamination, embossing, etc. to improve the beauty and recognition of the carton.

Quality inspection and packaging: Cartons produced are quality inspected to ensure accurate size, stable structure and clear printing. Then, qualified cartons are packaged for transportation and storage.

Features

Customization: Carton manufacturing is highly customized. Customers can customize the size, structure, material and printing content of cartons according to their needs and product characteristics.

Environmental protection: With the improvement of environmental awareness, more and more carton manufacturers have begun to use recyclable and degradable raw materials to reduce environmental pollution. At the same time, the recycling of cartons has also become a trend.

Efficiency: Modern carton manufacturing equipment is efficient and automated, which can greatly improve production efficiency and reduce costs.

Versatility: Cartons not only have the basic functions of protecting goods and facilitating transportation and storage, but also can achieve special functions such as anti-theft, moisture-proof and dust-proof through creative design.

Application scenarios

Cartons are widely used in various fields, including but not limited to:

Packaging industry: Cartons are one of the most common packaging materials in the packaging industry and are used to package various commodities, such as food, electronic products, daily necessities, etc.

Logistics industry: In the logistics process, cartons play a role in protecting commodities, facilitating transportation and storage. At the same time, the recycling of cartons also reduces logistics costs.

Warehousing industry: Cartons can be used as temporary packaging materials in the warehousing process to protect commodities from damage or contamination.

E-commerce platform: With the rise of e-commerce platforms, cartons have become one of the commonly used packaging materials for e-commerce platforms. E-commerce platforms need to select suitable cartons for packaging and distribution according to the size and characteristics of the commodities.

Maintenance and maintenance (precautions for the use of cartons)

Avoid moisture: Cartons are easily deformed by moisture in a humid environment, affecting the use effect. Therefore, during use and storage, cartons should be kept away from moisture or humid environments as much as possible.

Avoid heavy pressure: The load-bearing capacity of cartons is limited, and overweight items may crush the cartons, resulting in damage to the commodities. Therefore, when packing, the number and weight of items should be reasonably arranged according to the load-bearing capacity of the cartons.

Reasonable stacking: When stacking cartons, pay attention to the stacking height and stability to avoid collapse or damage of cartons. At the same time, avoid stacking cartons near flammable and explosive items to ensure safety.

Timely replacement: For damaged or deformed cartons, new cartons should be replaced in time to ensure the packaging quality and transportation safety of the goods.

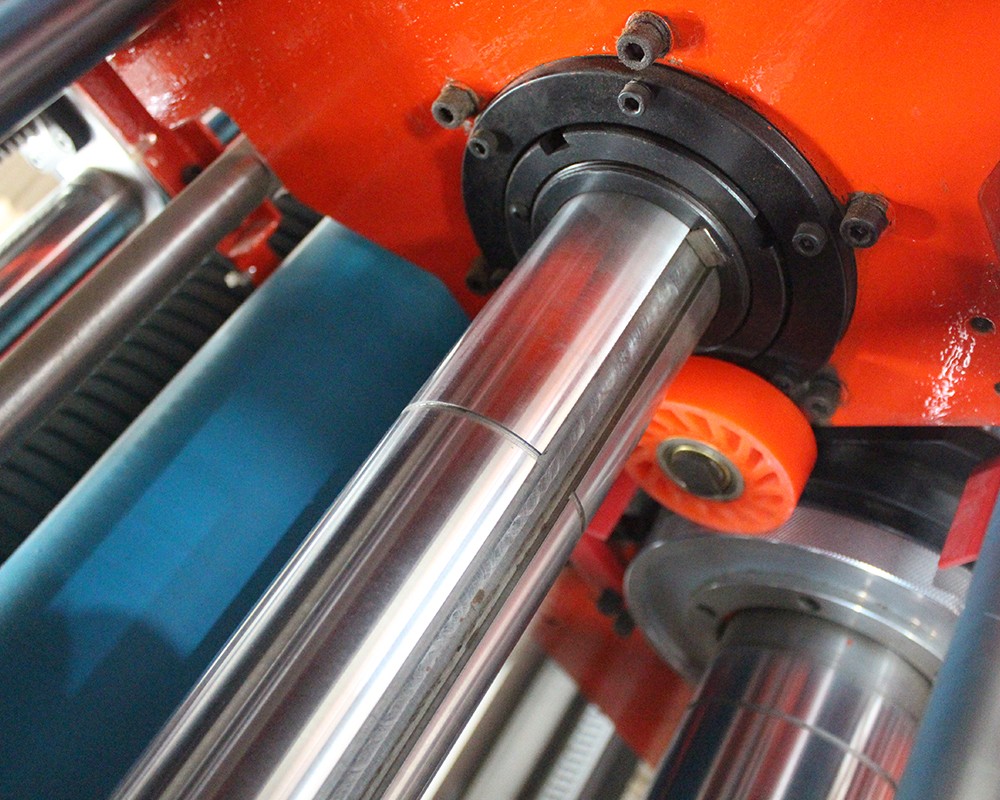

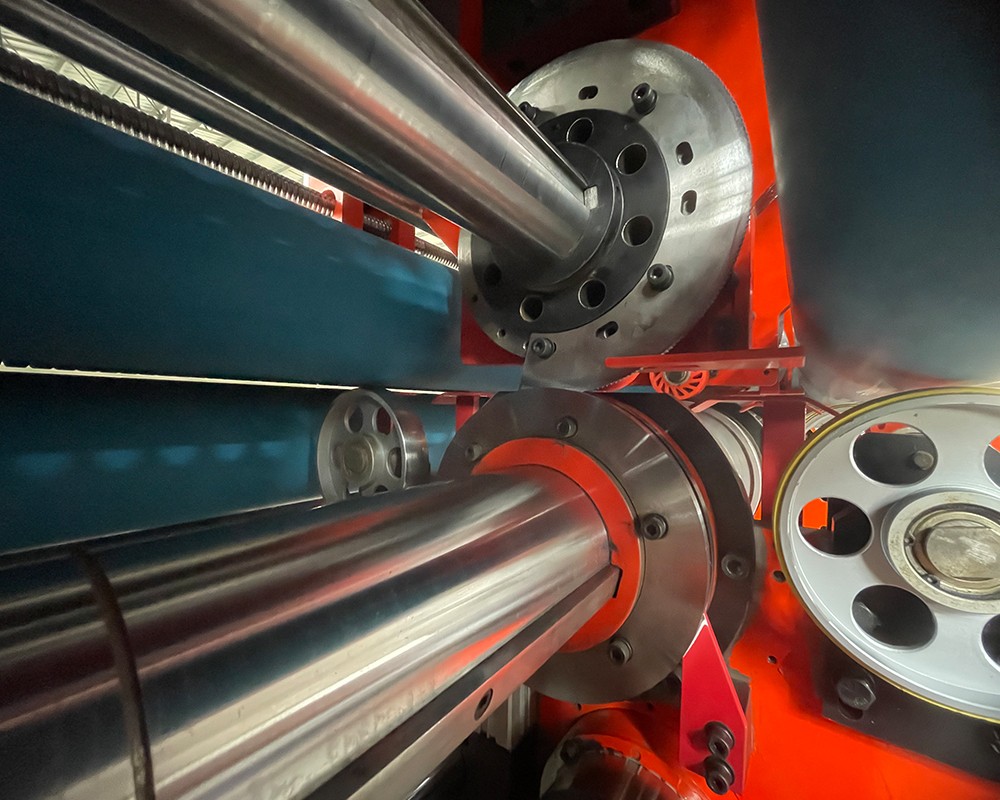

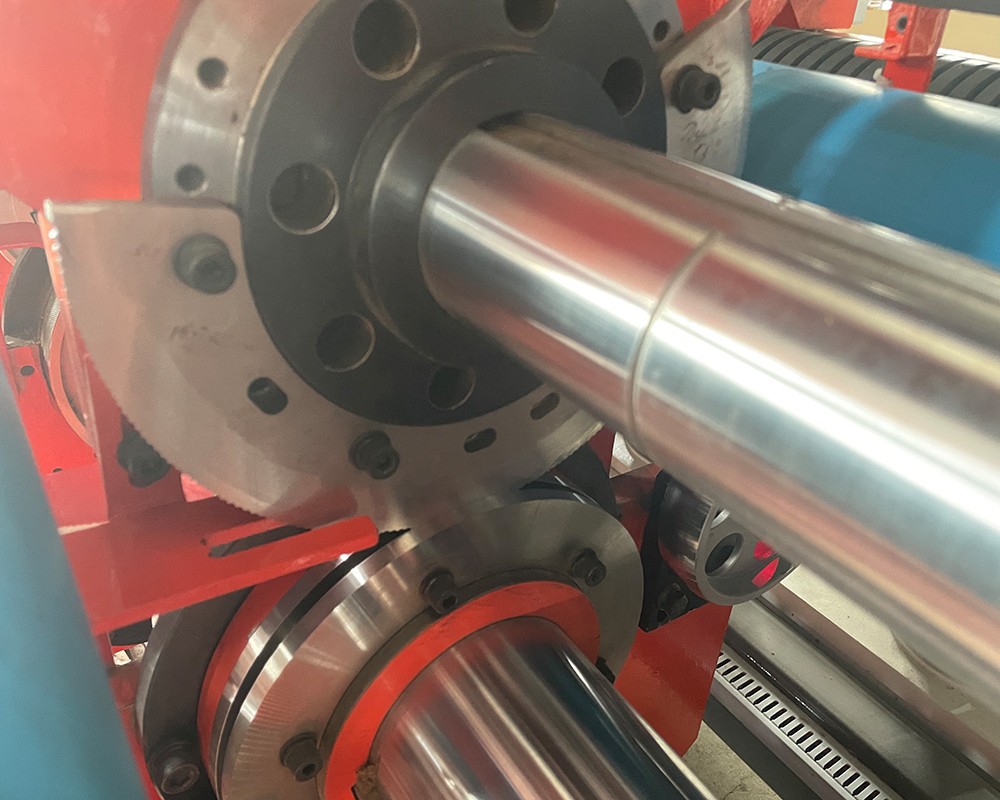

More Details about Product

Jingou packaging machinery Co.,ltd

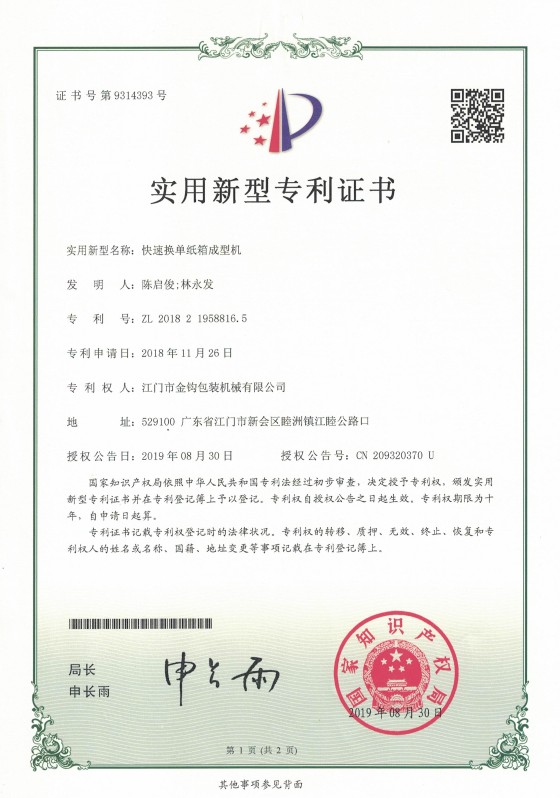

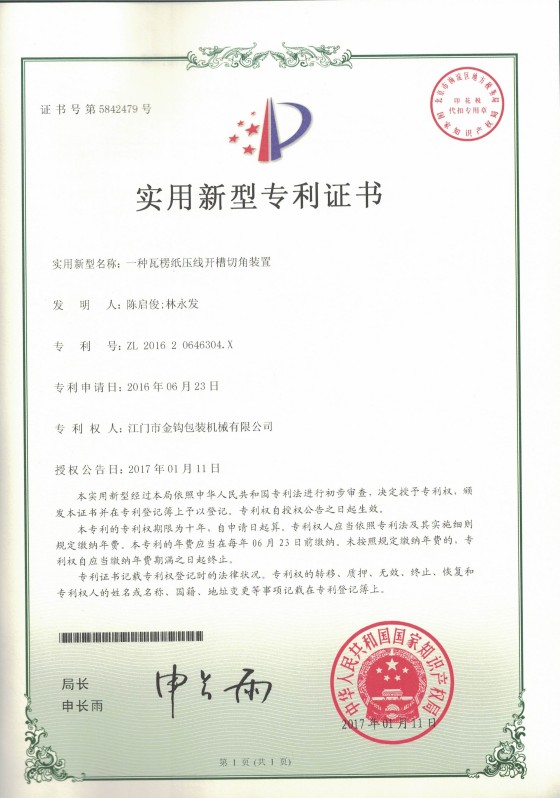

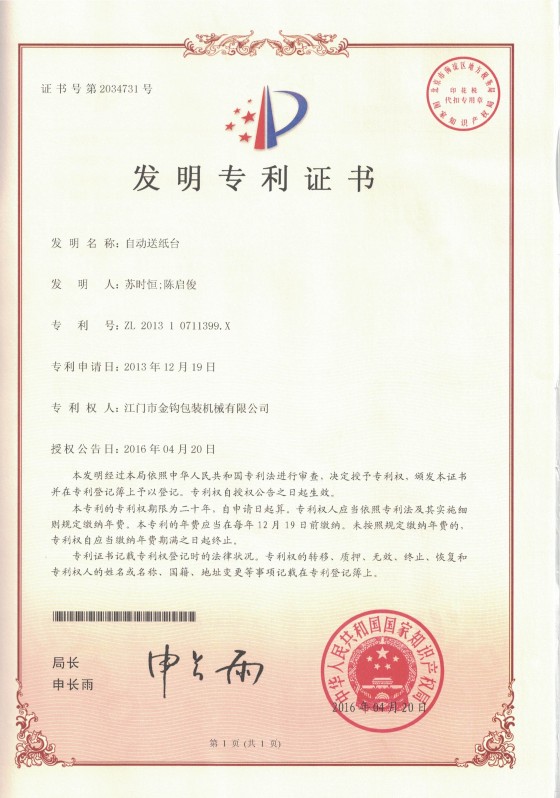

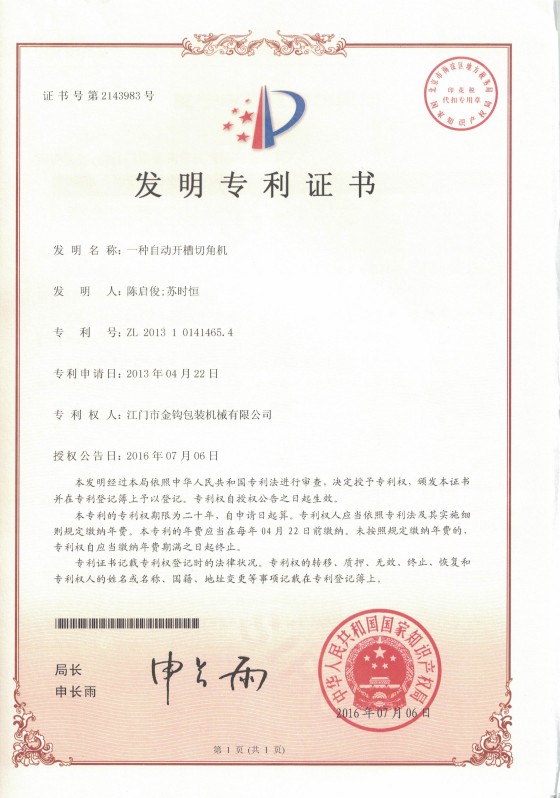

Jingou is a high-tech enterprise with forward thinking special designed,manufacturer of corrugated carton machine for small quantity orders .We had developed a very first auto thin slitter scorer machine which you can not find all over the world in 2009.And we keep working on developing functional box maker machine CK25 which earn many invention patents and utility model patents and passed CE certifications .Jingou machine had completed changed the low efficiency production mode of small quantity orders to meet the true needs of customers .