Custom Box Making Machine

Auto Thin Blade Slitter Scorer

-

+86-13702592807 WhatsApp

-

sales@jingoupack.com Email

Custom Box Making Machine is an automated equipment developed specifically for the production of custom corrugated cardboard boxes. It realizes the integrated custom manufacturing of multi-size and multi-style cartons through cutting, creasing, slotting and other processes.

Carton Box Making Machine Parameter

| Mode | ZBFY-AD2500 | |

| Blade/scorer | 4 blades 6 wires | 5 blades 8 wires |

| Feede | Manual | |

| Pressure Adjus | Auto | |

| Max.speed | 160m/min | |

| Max.feeding Width | 2600mm | |

| Max.slitting Width | 2500mm | |

| Min.sittin Gwidth | 140mm | |

| Min.feeding Length | 350mm | |

| Min.scoring Width | 40x160mm | |

| Sheet Thickness | 2-7mm | |

| Air Pressure | 0.4Mpa | |

| Main Motor Power | 6kW | 7kW |

| Dimension(L*W*H) | 1570*3450*1500mm | |

| Overall Net Weight | 2500kg | 2800kg |

Advantages of Carton Box Making Machine

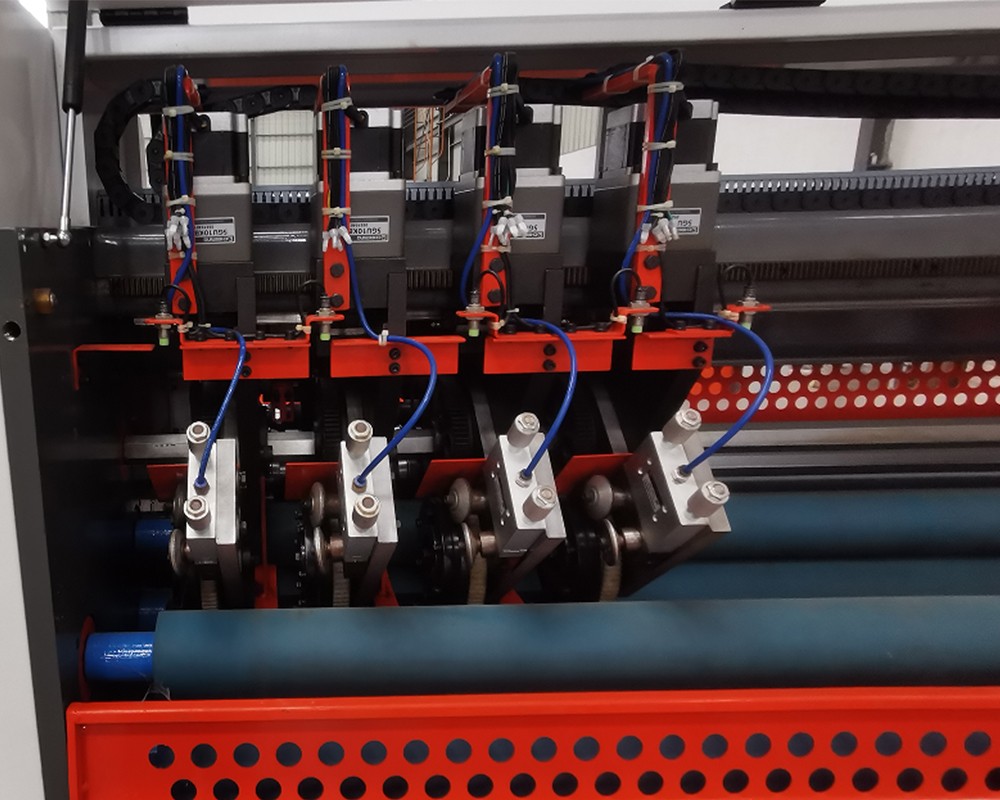

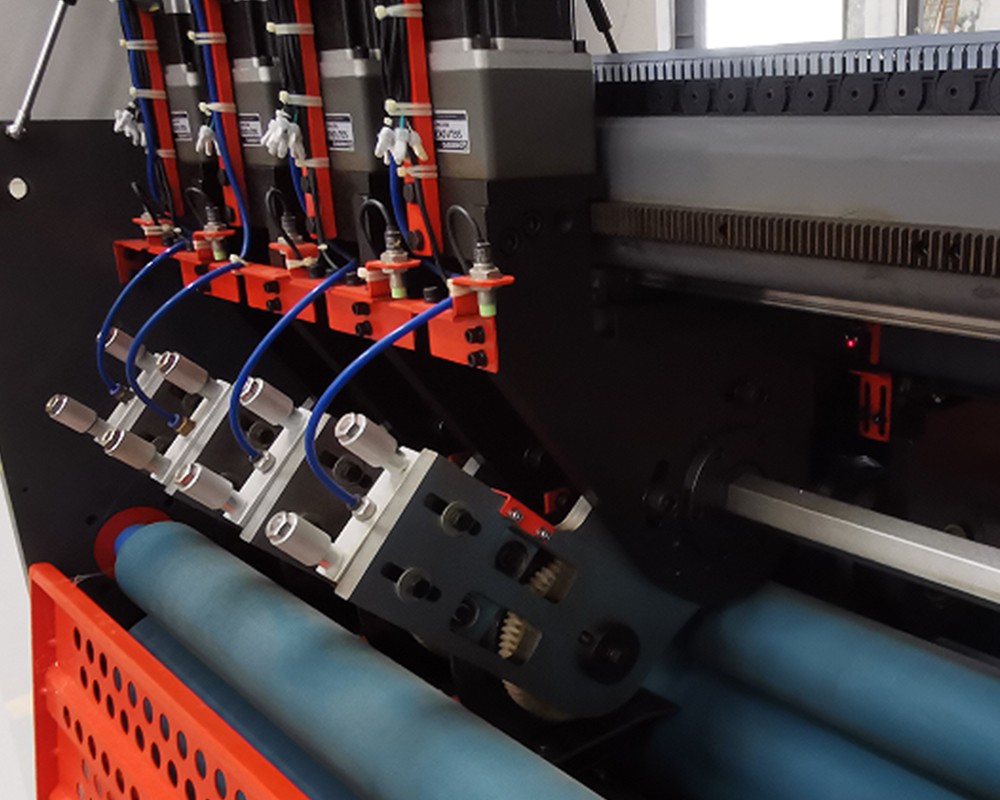

Modular knife line combination design

Provides multiple sets of blades and creasing wheel combinations to support the rapid switching of multi-specification boxes, significantly improve the efficiency of order change, and is suitable for scenarios with frequent order changes.

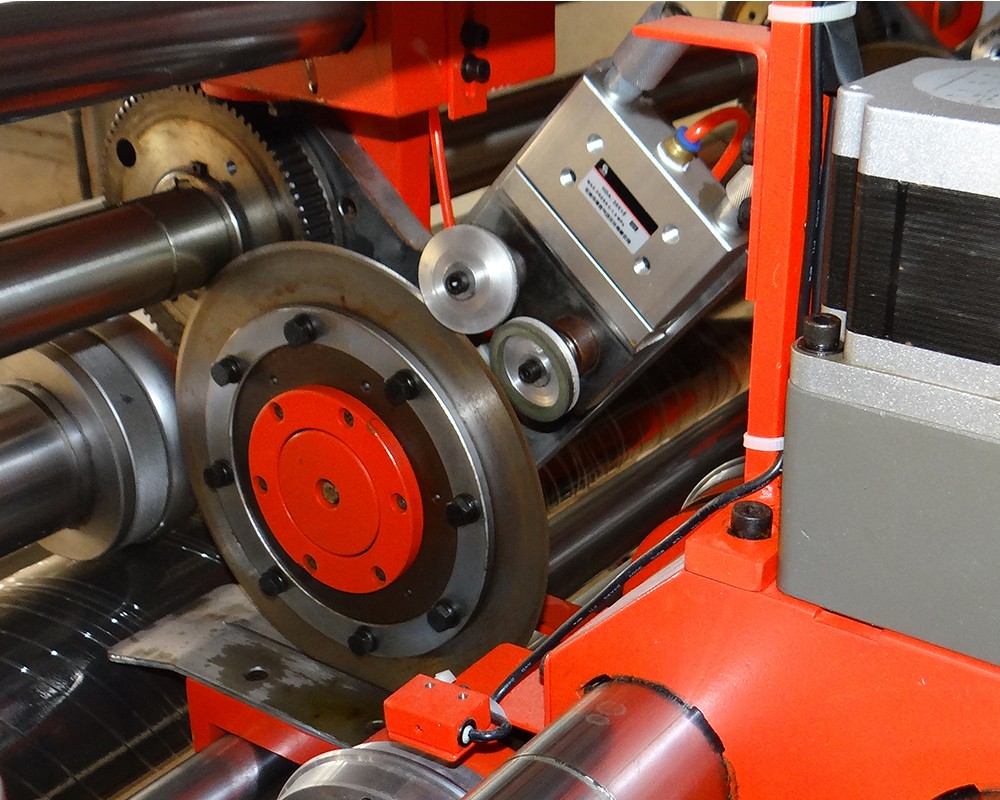

High-speed operation capability

The maximum operating speed can reach 160 meters/minute, meeting the high-tempo production needs of medium and large factories, while ensuring that the finished box is neat and the edges are smooth.

Wide-width cardboard support

The maximum feeding width can reach 2600mm, and the minimum slotting width is only 140mm. It is suitable for a variety of sizes from super-large packaging boxes to mini e-commerce boxes, with strong flexibility.

Intelligent pressure adjustment system

The automatic pressure adjustment structure can automatically match the optimal cutting pressure according to the thickness of the cardboard to ensure uniform creasing, clear cutting edges, and no paper jams.

Manual feeding operation is flexible and convenient

Equipped with a humanized manual feeding platform, it is convenient for operators to quickly load materials, especially suitable for multi-variety and small batch production lines.

Stable pneumatic system guarantee

During operation, it relies on 0.4Mpa air pressure to support the tangent operation, ensuring stable operation of the equipment and reducing mechanical wear and failure rate.

Applications of Carton Box Making Machine

Compact structure, saving space

The overall size of the equipment is controlled at 1570*3450*1500mm, which is suitable for flexible layout of small and medium-sized production workshops. At the same time, the weight of the whole machine is moderate and easy to install and maintain.

Custom Box Making Machine is used in the packaging manufacturing industry to help improve the efficiency of personalized customization of cartons

Supporting small batch production of multiple specifications, it is an important equipment for modern packaging plants to quickly respond to diversified market needs.

Custom Box Making Machine is used in the food and beverage industry to help achieve flexible management of food-grade packaging

Customized cartons according to orders, adapted to various product sizes, ensuring neat packaging and safe transportation.

Custom Box Making Machine is used in the home appliance and daily necessities industries to support exclusive packaging customization for large and special-shaped products. Its high and wide adaptability range and precise creasing performance make it an indispensable production equipment for customized packaging for large home appliance and furniture companies.

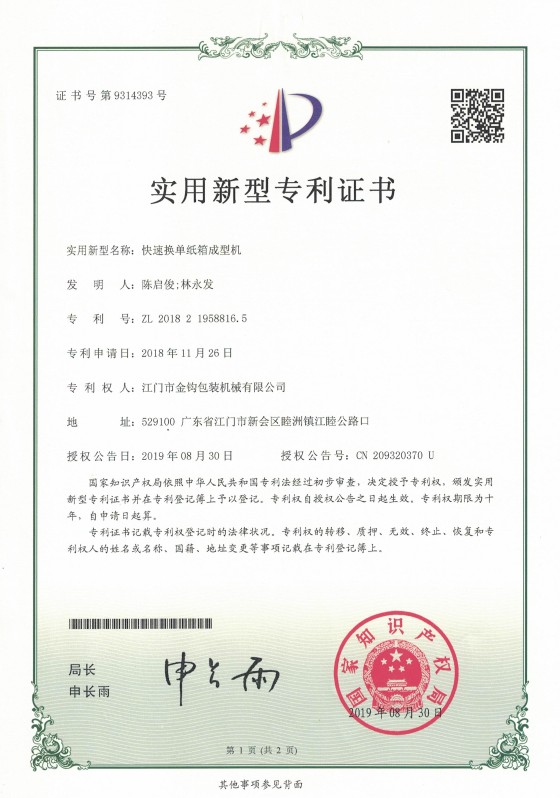

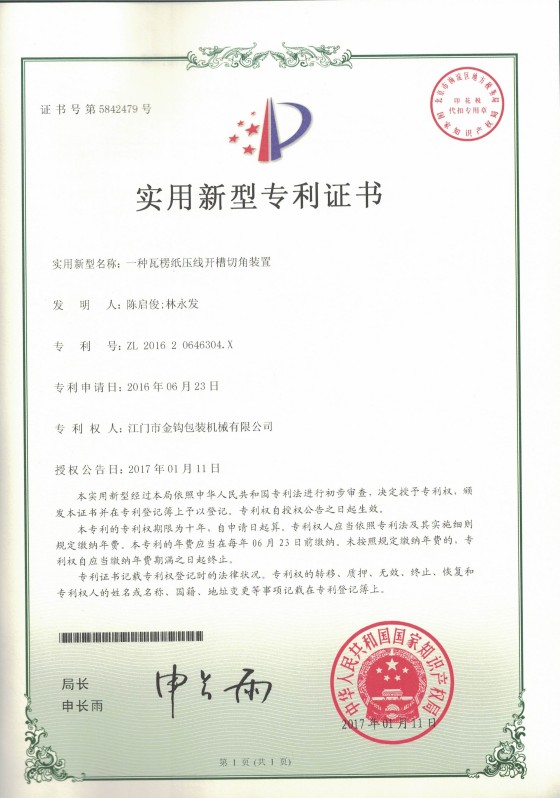

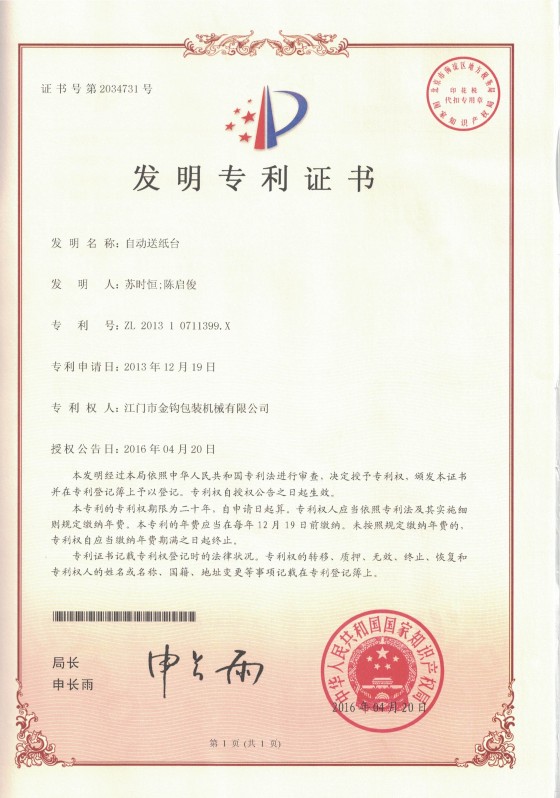

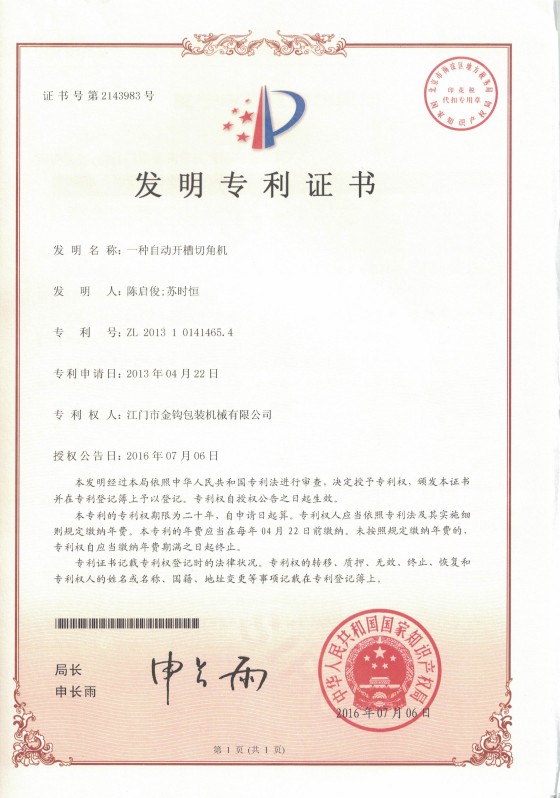

Jingou packaging machinery Co.,ltd

Jingou is a high-tech enterprise with forward thinking special designed,manufacturer of corrugated carton machine for small quantity orders .We had developed a very first auto thin slitter scorer machine which you can not find all over the world in 2009.And we keep working on developing functional box maker machine CK25 which earn many invention patents and utility model patents and passed CE certifications .Jingou machine had completed changed the low efficiency production mode of small quantity orders to meet the true needs of customers .