Corrugated Machinery

Cardboard Box Forming Machine

-

+86-13702592807 WhatsApp

-

sales@jingoupack.com Email

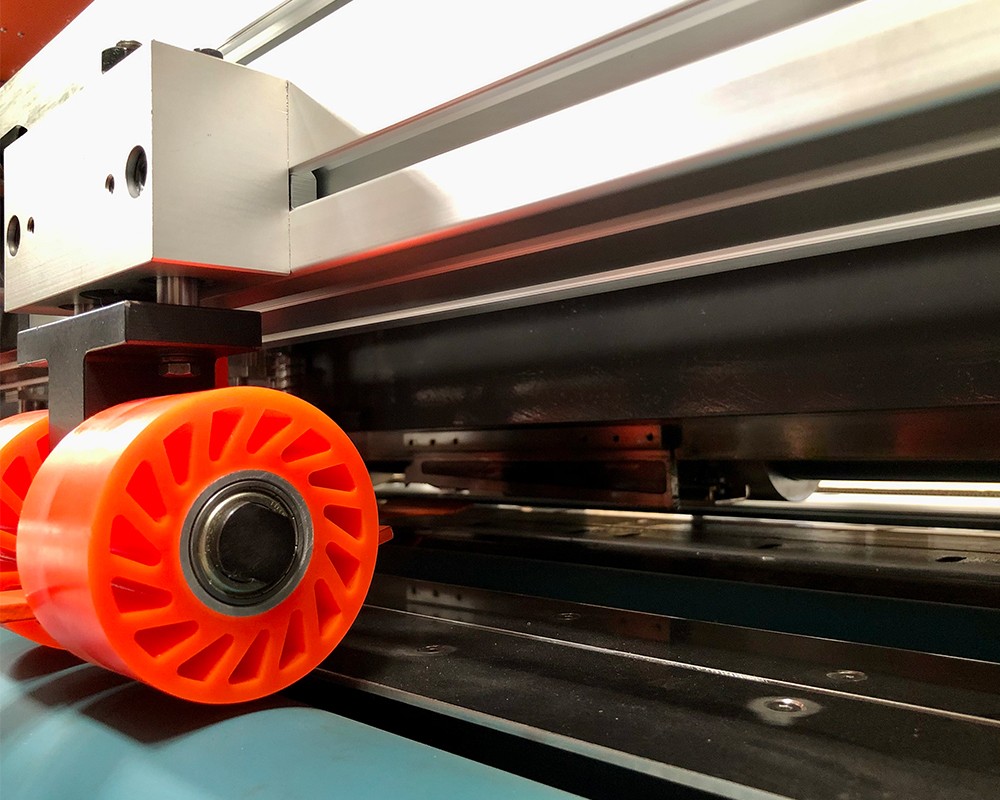

Corrugated Machinery is a kind of equipment specially designed for the production of corrugated cardboard and custom cartons. It completes the cutting, slotting, die-cutting and other processes of corrugated cardboard through precise technical processing to meet the needs of cartons of different sizes.

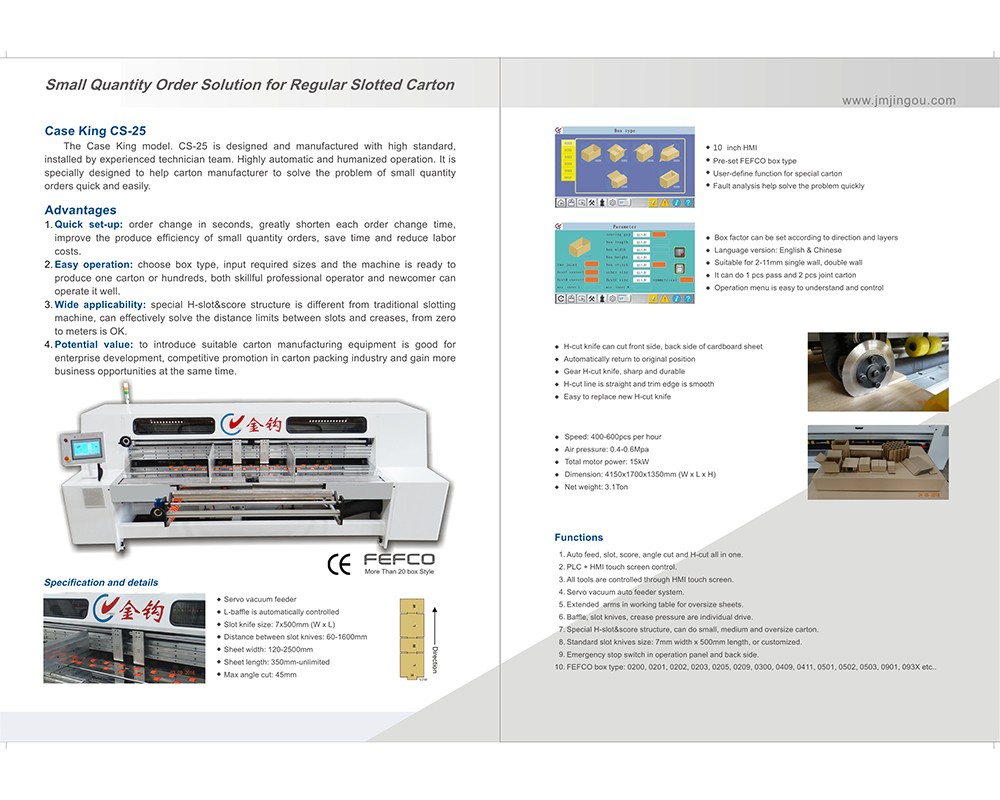

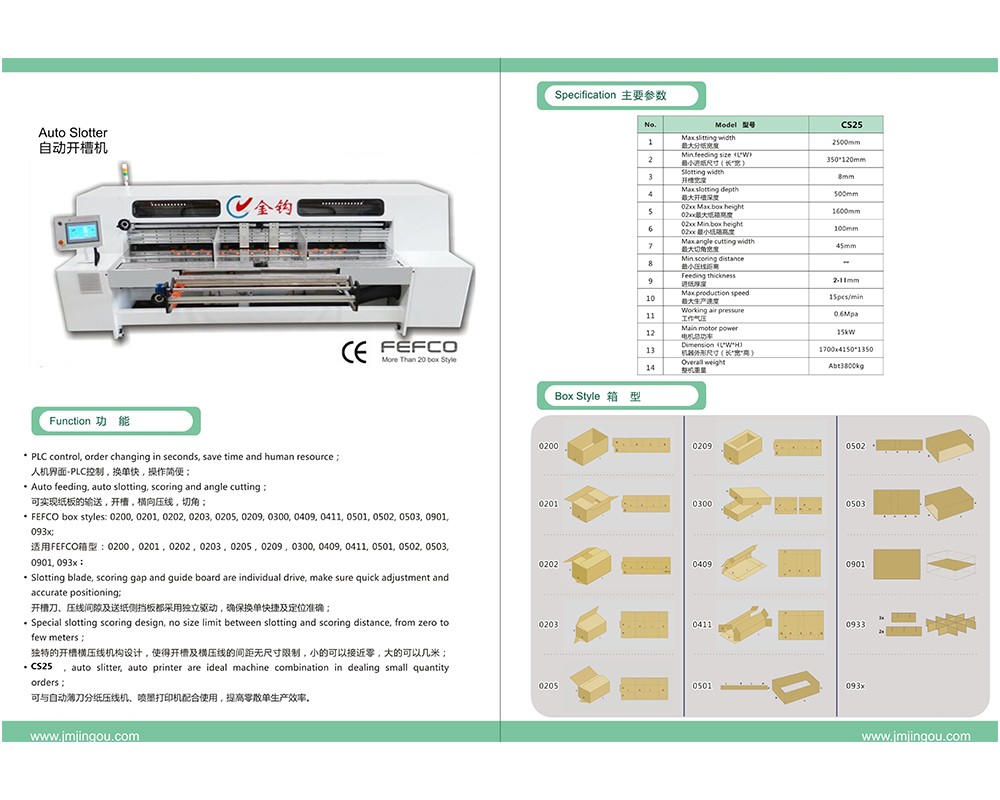

Corrugated Machinery Parameter

| Model | CS25 |

| Max.Feeding Size(W*L) | 2500mm*unLimited |

| Min.Feeding Size(W*L) | 120*350MM |

| Die-Cut Size | 140*190mm*lpcs |

| Slotting Width | 7mm |

| Max.slotting Depth | 500mm/400mm/300mm |

| 02xx Max.box Height | 1600mm/1800mm/2000mm |

| 02xx Min.box Height | 70mm |

| Max.angle Cutting Width | 45mm |

| Feeding Thickness | 2-11mm |

| Speed | 400-600pcs/h |

| Air Pressure | 0.3-0.6Mpa |

| Total Motor Power | Abt.15kW |

| Dimensuioin(W*L*H) | 4020*2050*1380mm |

| Overall Net Weight | Abt5000kg |

Advantages of Corrugated Machinery

Multi-specification adaptation

Supports a maximum cardboard width of 2500mm, suitable for the production of cartons of various sizes, and has a flexible feeding range, starting from the smallest 120mm x 350mm cardboard, with strong adaptability and can meet different process requirements.

High-precision cutting and die-cutting technology

With a maximum die-cutting capacity of 140mm x 190mm, it ensures that the cutting edges of product cartons are neat. Supports fine slotting functions to meet the needs of diverse carton design.

Fast production capacity

The maximum production speed reaches 600 cartons per hour, which greatly improves the efficiency of the production line, meets the needs of mass production, helps customers increase production capacity and shortens delivery cycles.

Efficient slotting depth control

The equipment supports cardboard processing with slotting depths of 500mm, 400mm, and 300mm, and can accurately process cardboard of various thicknesses and layers to ensure the strength and stability of the carton.

Flexible carton height adjustment system

The equipment can adjust the carton height range from 70mm to 2000mm according to production needs, meeting the production needs from small packaging to large boxes.

Energy-saving and efficient design

Adopting advanced energy-saving technology, the whole machine power is about 15kW, low energy consumption and high efficiency, and it can maintain stable output under long-term operation, reducing production costs.

Modern air pressure regulation system

Using 0.3-0.6Mpa air pressure system, it provides stable airflow support to ensure the smooth transportation of cardboard during the feeding process, avoid paper jams, and improve production stability.

Application of Corrugated Machinery

Corrugated Machinery is used in the packaging production industry to help improve the automation level and accuracy of carton production

It can automatically produce cartons of various specifications, suitable for packaging production companies that respond quickly to market demand, and improve production efficiency and packaging accuracy.

Corrugated Machinery is used in the daily consumer goods industry to help produce environmentally friendly, high-quality packaging

This equipment supports the mass production of environmentally friendly cartons, meeting the high requirements of the daily consumer goods industry for packaging beauty, strength and safety.

Jingou packaging machinery Co.,ltd

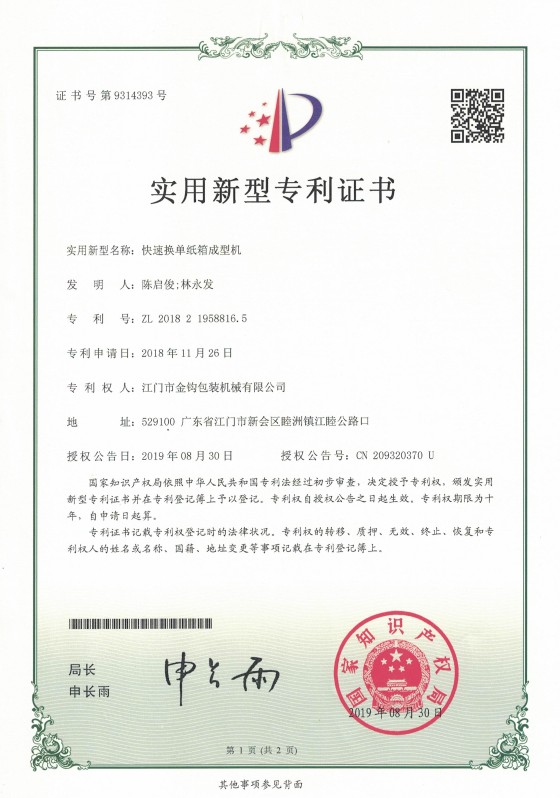

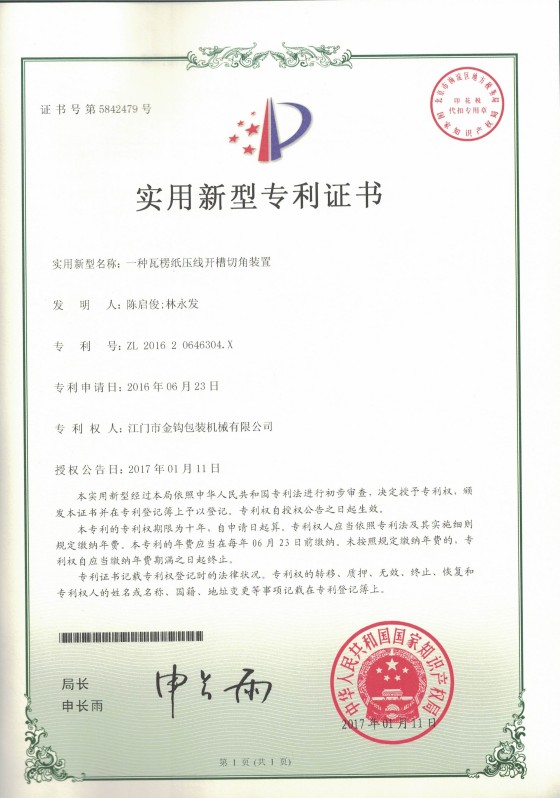

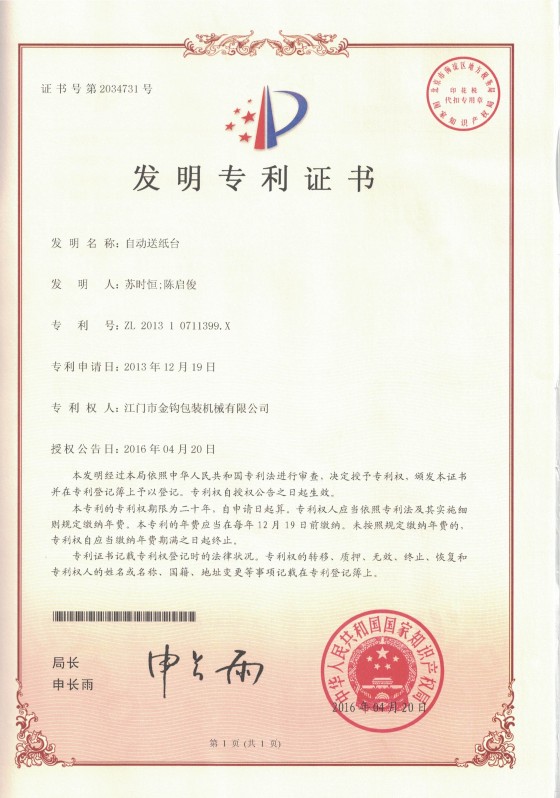

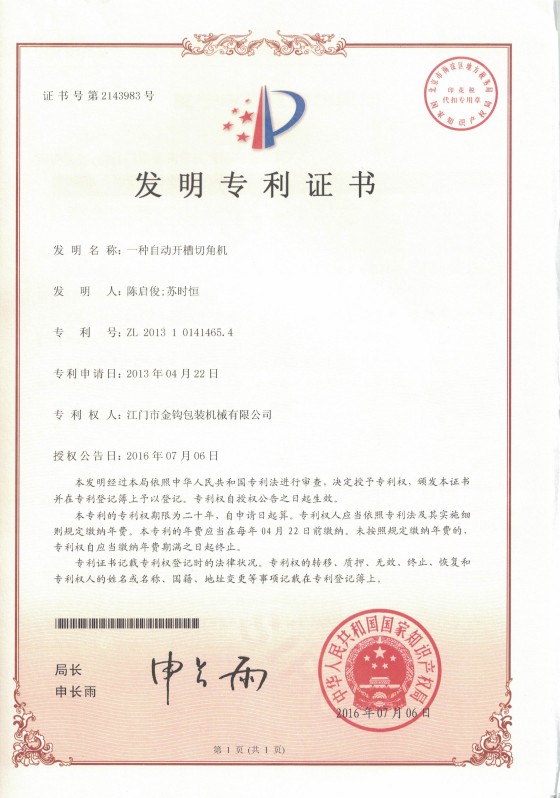

Jingou is a high-tech enterprise with forward thinking special designed,manufacturer of corrugated carton machine for small quantity orders .We had developed a very first auto thin slitter scorer machine which you can not find all over the world in 2009.And we keep working on developing functional box maker machine CK25 which earn many invention patents and utility model patents and passed CE certifications .Jingou machine had completed changed the low efficiency production mode of small quantity orders to meet the true needs of customers .