Corrugated Box Making Machinery

Corrugated Box Making Machinery is usually composed of multiple modules such as corrugated cardboard production line, automatic slotting and creasing machine, die-cutting machine, printing machine, gluing machine and automatic strapping machine. The overall structure is mainly high-strength steel frame, the shell adopts electrostatic spraying process, the core operating parts adopt imported bearings and alloy steel cutters, and the equipment is equipped with a touch-screen PLC operating system to achieve one-click parameter input, multi-specification switching and remote fault diagnosis. It is a type of automated equipment system designed for corrugated cardboard processing and carton manufacturing, and is widely used in the paper packaging industry.

auto rotary slotter machine Features

① Multifunctional whole line configuration, one-stop carton forming solution

The whole line Corrugated Box Making Machinery includes modules such as cardboard conveying, slotting and creasing, die-cutting, gluing, box gluing, stacking and packaging, which fully covers all processes of carton forming. The maximum size of the standard configuration is 1600mm x 3000mm, and the equipment can be customized to meet the packaging needs of large items such as furniture, electrical appliances, and logistics. All modules are managed in a linked manner through a centralized control system to avoid manual connection errors and greatly improve the consistency and efficiency of the production line.

② High-speed intelligent control system, more than 30% more efficient than traditional equipment

The core of Corrugated Box Making Machinery adopts Siemens PLC and servo control system, with a 10-inch touch screen operation interface, to achieve automatic setting and one-button switching of parameters such as speed, size, and indentation position. The maximum operating speed can reach 300 pieces/minute. While maintaining the error range of ±0.3mm, the efficiency is more than 30% higher than that of traditional single equipment, greatly shortening the order delivery time and enhancing production flexibility.

③ Energy-saving design and silent operation to meet the requirements of green and environmentally friendly factories

The mechanical operation noise is controlled within 75dB, and the key driving parts are equipped with imported shock-absorbing pads and silent chains to create a lower noise working environment. Corrugated Box Making Machinery adopts a variable frequency motor drive system, which automatically adjusts energy consumption according to the load, and the power of the entire line is controlled in the range of 10kW~35kW, which effectively reduces the operating electricity cost and meets the European and American green factory certification standards.

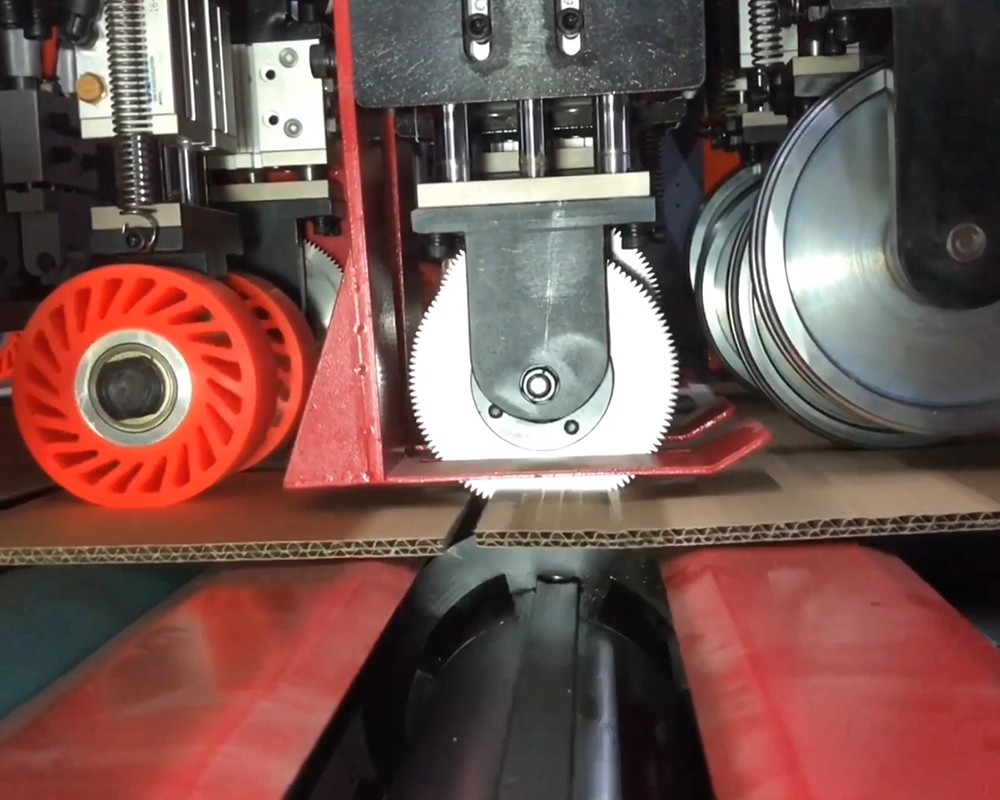

④ High-precision slotting and creasing system, with a finished product qualification rate of more than 99%

The key slotting components are made of high-strength carbon alloy steel, and the blade thickness is only 7mm, ensuring that the slotting lines are neat and without burrs. The creasing wheel adopts a multi-stage pressure adjustable design, which is suitable for three-layer, five-layer and seven-layer corrugated cardboard. The creasing depth is consistent and symmetrical, ensuring that the subsequent folding process does not explode the line, and the finished product qualification rate is stable at more than 99%.

⑤ Support remote maintenance and data recording to improve management efficiency

The whole machine supports remote network maintenance, and technicians can remotely upgrade the system program and detect faults through the network. At the same time, it has the function of automatic recording and exporting production data, including output, line change time, fault records, etc., and can be connected to the MES system, which is convenient for the factory to do refined management and equipment utilization analysis.

Auto Rotary Slotter Machine Application

① Large local carton factory in Chennai, India

In a large packaging factory in Chennai, India with an annual output of more than 100 million square feet of cartons, the Corrugated Box Making Machinery is used to quickly switch export carton orders of different specifications. The local high temperature and dusty environment places high demands on the durability of the Corrugated Box Making Machinery. With its excellent sealing structure and self-cleaning dust removal system, the Corrugated Box Making Machinery has a stable operation cycle of more than 300 days, effectively ensuring the order delivery capacity.

② Guadalajara, Mexico E-commerce Logistics Storage Box Supplier

With the explosive growth of local e-commerce in Mexico, a carton factory in the city introduced this equipment to customize standard express cartons for e-commerce companies such as Amazon and Mercado Libre. Through the system preset function, one-click switching of 5 express box size templates effectively saves 40% of line change time, winning an absolute advantage for customers in order delivery.

③ Krakow, Poland Precision Instrument Packaging Company

A high-end instrument exporter in Poland uses Corrugated Box Making Machinery to produce five-layer thickened pressure-resistant cartons. Due to the strict requirements of the product for anti-fall and moisture-proof, the Corrugated Box Making Machinery provides multi-line indentation and increased die-cutting accuracy setting functions to ensure that the carton's pressure resistance reaches more than 650N/m², and with PE liner packaging, it successfully meets customers' transportation compliance certification in the EU market.

④ Saudi Arabia Riyadh Food Packaging Production Line

In the Riyadh Industrial Zone, a food packaging factory purchased this set of Corrugated Box Making Machinery for the efficient production of outer boxes for milk, biscuits, seasonings, etc. The Corrugated Box Making Machinery supports the production of supporting packaging for R600a environmentally friendly coolant. With a high production capacity of 280 pieces per minute, it supports an 8-hour two-shift system every day, and produces more than 30 million cartons per year.

Previous: Corrugated Cardboard Box Making Machine