Corrugated Cardboard Box Making Machine

corrugated cardboard box making machine is suitable for batch processing of three-layer to seven-layer corrugated cardboard. The main body adopts heavy steel frame structure, the appearance is treated with high-temperature electrostatic spraying, equipped with transparent observation window and emergency stop button, the main operating mechanism such as die-cutting knife, creasing roller, paper feeding roller are all high-precision processed parts, with intelligent PLC control system, it is a comprehensive equipment for automatic cutting, creasing, slotting, folding, gluing, forming and stacking of corrugated cardboard.

Corrugated Cardboard Box Making Machine Features

① High automation control system - improve work efficiency

Corrugated Cardboard Box Making Machine is equipped with Siemens PLC intelligent control system, which is operated through a 10-inch touch screen. Users can quickly set parameters such as carton size, slot width, folding line depth, etc. The fully automatic order change time is less than 60 seconds, and it supports 20 sets of recipe storage to meet the needs of fast switching of multiple orders. The whole machine can realize unattended operation, saving labor input.

② Multifunctional integrated structure - Reduce the floor space of the factory

Corrugated Cardboard Box Making Machine integrates functional modules such as feeding, printing, die-cutting, slotting, and bonding to form a compact all-in-one machine design. The length, width, and height of the machine are: 9800mm×3100mm×2200mm, and the floor space is only about 30 square meters. The highly integrated structure effectively solves the problem of tight factory space and is suitable for upgrading and transformation of small and medium-sized packaging companies.

③ High-speed stable and reliable operation - meet mass production

Corrugated Cardboard Box Making Machine runs at a speed of up to 200 sheets of cardboard/minute, driven by a servo motor, and the error is controlled within ±0.5mm. All bearings are NSK brand, and key transmission components are made of alloy steel to support long-term 24-hour uninterrupted operation. The annual average equipment failure rate of the entire line is less than 0.5%, effectively ensuring production continuity.

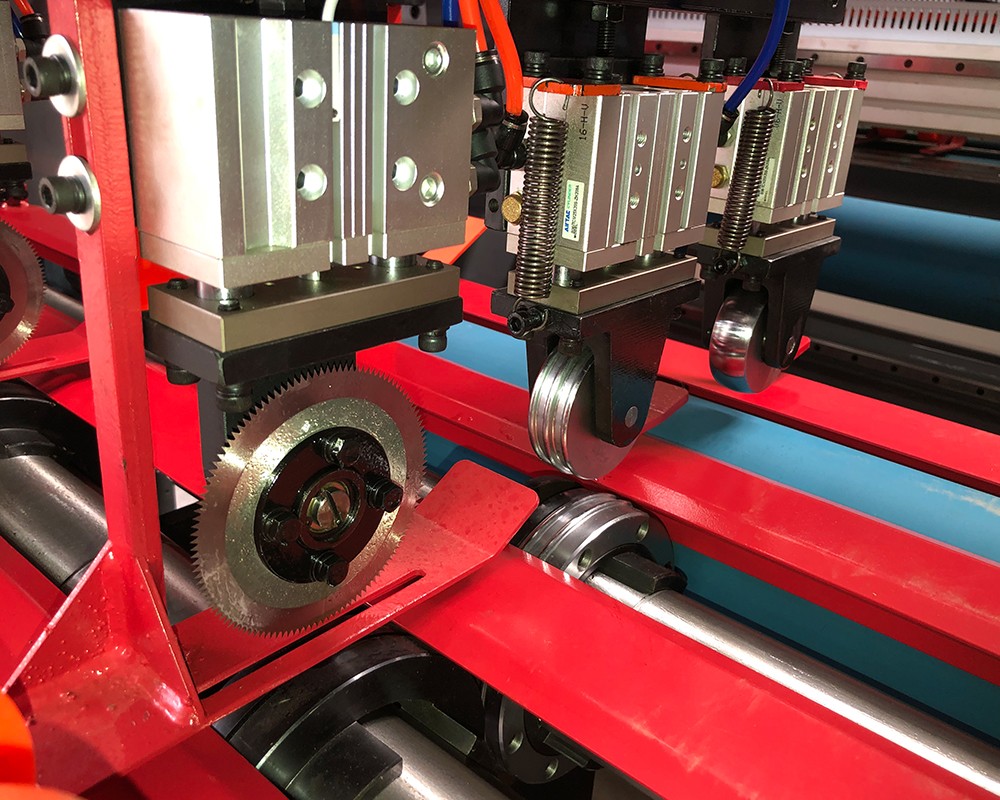

④ High-precision cutting and creasing system - ensure the quality of finished products

The Corrugated Cardboard Box Making Machine adopts a 7.5mm thin blade design, and the cutting edge is smooth and flat; the creasing roller has a multi-speed pressure adjustable function, the creasing depth is consistent, and the left and right spacing is accurate, ensuring that the carton will not explode during the subsequent folding process. The equipment supports double-head configuration, which is suitable for the production of special-shaped boxes, large cardboards or orders of different sizes.

⑤ Energy-saving and silent design - in line with environmental protection production requirements

The noise of the Corrugated Cardboard Box Making Machine is controlled below 72dB, and imported silent chains and rubber rollers are used to significantly reduce operating noise. The main motor adopts variable frequency drive, which automatically adjusts the power according to the load, and the comprehensive energy consumption is about 25% lower than that of traditional equipment. Supports the production of cartons with R600a environmentally friendly coolant, which complies with European and American environmental protection regulations.

Corrugated Cardboard Box Making Machine Application

① E-commerce logistics carton factory in Ho Chi Minh City, Vietnam

In a large logistics carton manufacturer in Ho Chi Minh City, Vietnam, the Corrugated Cardboard Box Making Machine is used to manufacture standard cartons for Shopee and Lazada platforms. Customers can quickly produce more than 10 express boxes of different sizes by presetting multiple sets of templates, with a daily production capacity of 120,000, which significantly improves the packaging response speed of e-commerce.

② Home appliance packaging box supplier in Chicago, USA

The Corrugated Cardboard Box Making Machine runs stably on the production line of a home appliance packaging manufacturer in Chicago, mainly serving packaging orders for home appliance brands such as Whirlpool and LG. In response to the heavy-duty packaging box requirements for large appliances, the equipment is specially equipped with double creasing knives and high-strength die-cutting modules to ensure that the carton load-bearing capacity meets transportation requirements.

③ Medical device export packaging factory in Stuttgart, Germany

In the Stuttgart area of Germany, a medical device exporter uses this equipment to mass-produce thickened medical packaging cartons. Since medical equipment has extremely high requirements for transportation protection, the factory uses five-layer corrugated cardboard with the automatic die-cutting and precise slotting system of this equipment to effectively ensure the safety and stability of the product during transportation.

④ Dubai Fresh Packaging Center, UAE

In a fresh fruit export processing factory in Dubai, this equipment is used to customize fruit export cartons. The machine supports fast switching of standard box templates in different countries, and adds a processing procedure for reserved grooves for absorbent lining boards. The annual production of standard export fruit cartons exceeds 40 million, and the service brands include Chiquita and Zespri.