Cardboard Grooving Machine for Box Making

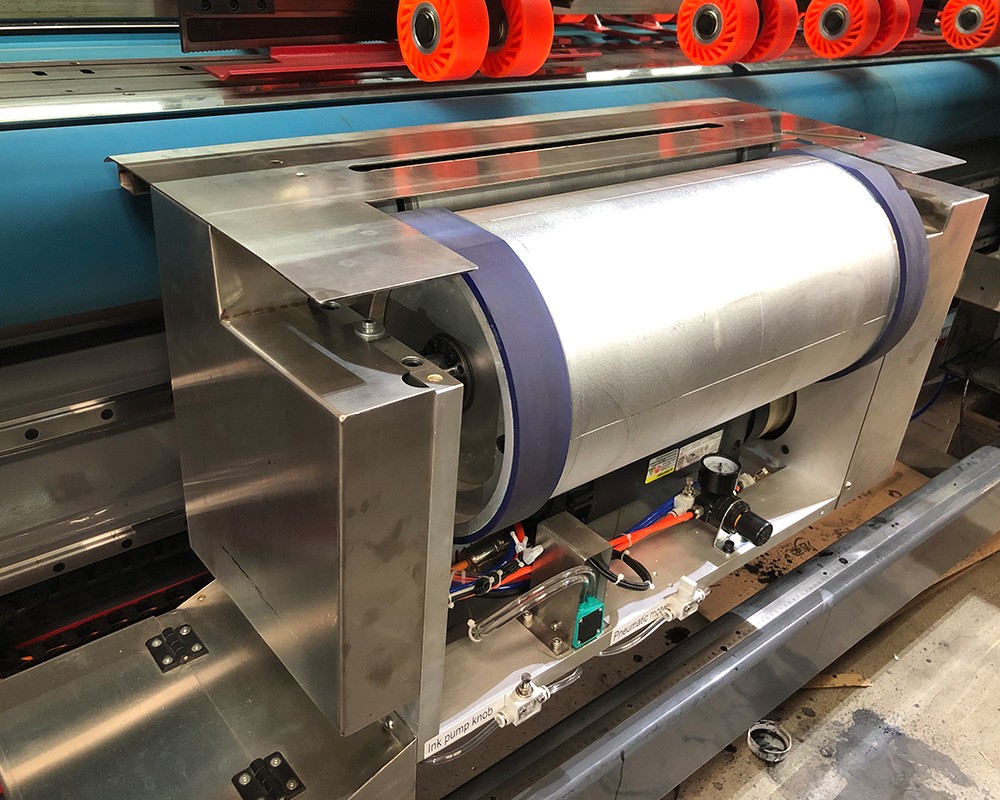

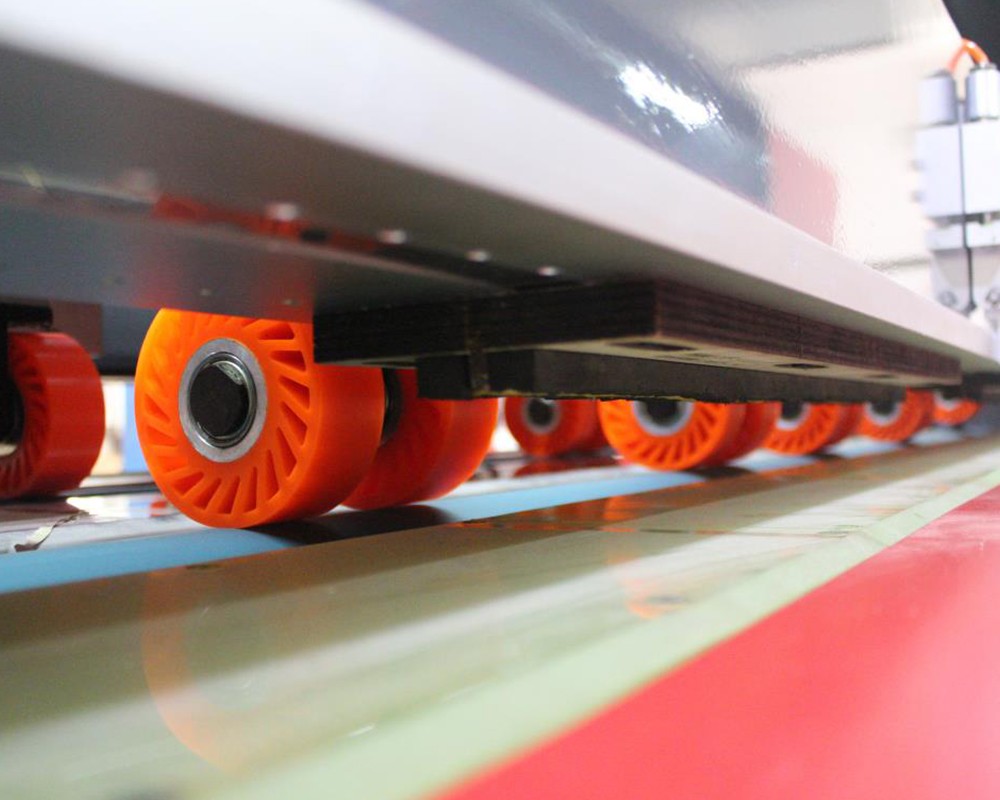

Cardboard Grooving Machine for Box Making is manufactured by welding industrial-grade steel frames. The machine body size is 4050mm x 700mm x 2000mm, with an overall net weight of about 8000kg. The front end is equipped with an automatic paper feeding system, the middle section is the core cutting and slotting module, and the rear end is equipped with an automatic paper discharge area and a pneumatic flattening device. With the motor drive system with a total power of about 15kW, it is a high-precision automatic slotting equipment designed specifically for the cardboard packaging industry.

Cardboard Grooving Machine for Box Making Features

① Efficient production capacity support - 600 pieces of forming processing capacity per hour

The production speed of Cardboard Grooving Machine for Box Making can reach 400-600 pieces/hour, which is at the mid-to-high-end production line efficiency standard in the current industry. This efficiency is mainly due to its double-knife parallel working mechanism. Each feeding can realize the simultaneous processing of two pieces of cardboard, shortening the unit time operation cycle. The machine uses an intelligent variable frequency speed regulation system, which can flexibly adjust the feeding speed and slotting beat according to the thickness and structure of the paper, which can not only ensure high production, but also effectively reduce the risk of material waste. For medium and large factories with frequent order changes and batch alternation, CK25 provides highly flexible and controllable production capacity guarantee.

② Precision cutting system - 7mm groove width + 500mm depth

The standard groove width of Cardboard Grooving Machine for Box Making is 7mm, and the maximum depth supports 500mm, which is suitable for the deep groove requirements of various composite boards and thick cardboards. It is suitable for packaging forms such as wine boxes, gift boxes, and book boxes that have strict requirements on the strength of three-dimensional structures. The maximum width of the tool angle cutting is 45mm, and it is equipped with an adjustable angle module, which can perform mixed processing of straight grooves and angled V grooves to meet the production needs of different structural box types and improve the folding accuracy and structural firmness of the finished box.

③ Wide-width adaptability - Maximum 2500mm format without length limit

CK25 has a maximum paper feed width of 2500mm, and the length can be extended infinitely, which greatly improves the flexibility of the equipment in processing oversized cardboard. Conventional machines are usually limited to a format of 1000mm-1500mm, while this machine supports double-joined materials and plate processing, and is suitable for exporting large-sized cartons, wine gift boxes, home appliance packaging and other scenarios. At the same time, its minimum paper feed size is 120mm*350mm, and it can also handle small batches of hardcover box production. It is a combination of the versatility and professionalism of Cardboard Grooving Machine for Box Making.

④ Energy-saving and stable operation - 15kW total power + low air pressure drive

The total power of Cardboard Grooving Machine for Box Making is about 15kW. Through the energy-efficient motor drive system and PLC precise control, it achieves a dual balance of energy saving and performance. The working pressure of the air pressure part only requires 0.3~0.6Mpa, which significantly reduces the compressed air consumption compared to traditional pneumatic machinery, and is suitable for long-term continuous operation. The built-in overload protection and temperature control detection system can automatically alarm and power off, reduce the failure rate, and reduce maintenance costs. The whole machine complies with CE and ISO standards and supports long-term high-load operation.

Cardboard Grooving Machine for Box Making Application

① Hamburg, Germany - High-end wine box packaging production workshop

In Hamburg, Germany, a packaging company serving European high-end red wine brands purchased a CK25 cardboard grooving machine for customized gift box production. The company provides customized wine box packaging for brands Château Margaux Europe and Weingut Keller, which requires high precision, stable structure and strong aesthetics. The double-knife parallel processing and precise 7mm V-groove of the Cardboard Grooving Machine for Box Making make the corners of the packaging box closely aligned when folded, without the need for multiple adjustments, greatly shortening the mold change time. The company particularly values the machine's adaptability to cardboards of different thicknesses (2mm~11mm), and one machine can be used for multiple purposes, effectively saving equipment investment costs.

② Dubai, UAE - Luxury Gift Box Customization Workshop

Emirates Luxury Pack in Dubai is a production company specializing in the customization of high-end perfume, jewelry, and e-cigarette gift boxes. They provide customized packaging services to customers such as Cartier Middle East and Chanel Dubai. Since the Cardboard Grooving Machine for Box Making can reach a maximum paper feed width of 2500mm and a groove depth of 500mm, it is very suitable for large-scale top and bottom cover structures and special-shaped box designs, improving the structural integrity of the product. Through the high-speed mode supported by the equipment, they can complete multiple batches of orders in a short time and provide customers with fast delivery services.

③ Chicago, USA - Book Binding Factory

In Chicago, Master Binding Solutions uses CK25 to fold and pre-groove gray boards with a thickness of 3~5mm for the production of book covers for high-end albums, commemorative albums, and wedding albums. The book cover requires precise fold lines, especially after the thickening of the plate, which requires higher V-groove symmetry. The Cardboard Grooving Machine for Box Making can achieve ±0.1mm precision error control, so that the book will not warp or crack after forming, which greatly improves the craftsmanship and brand grade of the book. The data can be preset through the touch panel, corresponding to different layouts, and the recipe can be switched with one key to improve work efficiency.

④ Shenzhen, China - Export-oriented electronic product packaging factory

LinkView Packaging Ltd. in Shenzhen mainly deals in paper boxes for export electronic product packaging, with a large order volume and a wide variety of products. The CK25's high output rate of 600 pieces/hour and double-sheet processing function solve the factory's long-term pressure of mass delivery. The factory also uses the QR code printing module installed on the Cardboard Grooving Machine for Box Making to connect with the ERP system to achieve automatic material sorting and data tracking. With the efficient automated assembly line, the annual production capacity has increased by 40%, and its customers include brands such as Anker and Xiaomi International.