Corrugated Paper Box Machinery

Corrugated Paper box machinery is a high-efficiency mechanical system designed for corrugated box manufacturing. It integrates a number of modern technologies and can complete a series of automated processes such as printing, slotting, corner cutting, folding, and gluing of cardboard. The external structure of the machine is welded with thickened steel plates, equipped with a PLC intelligent control system and a high-definition touch screen. The overall size of the machine can be customized on demand and can be flexibly configured according to the customer's cardboard specifications and process flow.

Corrugated Paper Box Machinery Features

① Fully automated control - improve efficiency and reduce manpower investment

The core advantage of Corrugated Paper Box Machinery lies in the automated control of the entire line. Starting from the feeding of cardboard, printing, slotting, corner cutting, folding, and gluing are completed in sequence. The whole process is precisely controlled by the PLC system without manual intervention. The entire line adopts servo motor drive and photoelectric detection technology to achieve precision control within ±0.5mm. The printing part uses a flexographic printing unit to ensure bright colors and no ghosting; the slotting and corner cutting modules support arbitrary adjustment of specifications to meet the needs of different carton structures. It is particularly suitable for factories with large orders and frequent batch changes, effectively solving problems such as low labor efficiency and high error rate. Customers reported that after using the machine, a single production line saved 40% of labor and increased production efficiency by 60%.

② Multi-specification compatible design - meeting different carton sizes and structures

The design of Corrugated Paper Box Machinery fully considers the compatibility of cartons of different sizes. Its paper feeding system supports cardboard widths from a minimum of 300mm to a maximum of 2500mm, and cardboard thicknesses from 2mm to 11mm. Each module of Corrugated Paper Box Machinery, such as crimping, slotting, and folding, is equipped with automatic adjustment functions, and processing specifications can be quickly switched without changing tools or parts. This function is particularly suitable for multi-variety mixed-line production, such as home appliance packaging, food gift boxes, e-commerce express boxes and other different types of carton production tasks. The order change operation is fast and stable, meeting the diverse market needs, and is an ideal choice for buyers to expand their product lines.

③ High-strength and durable structure - ensuring stable operation of continuous operation

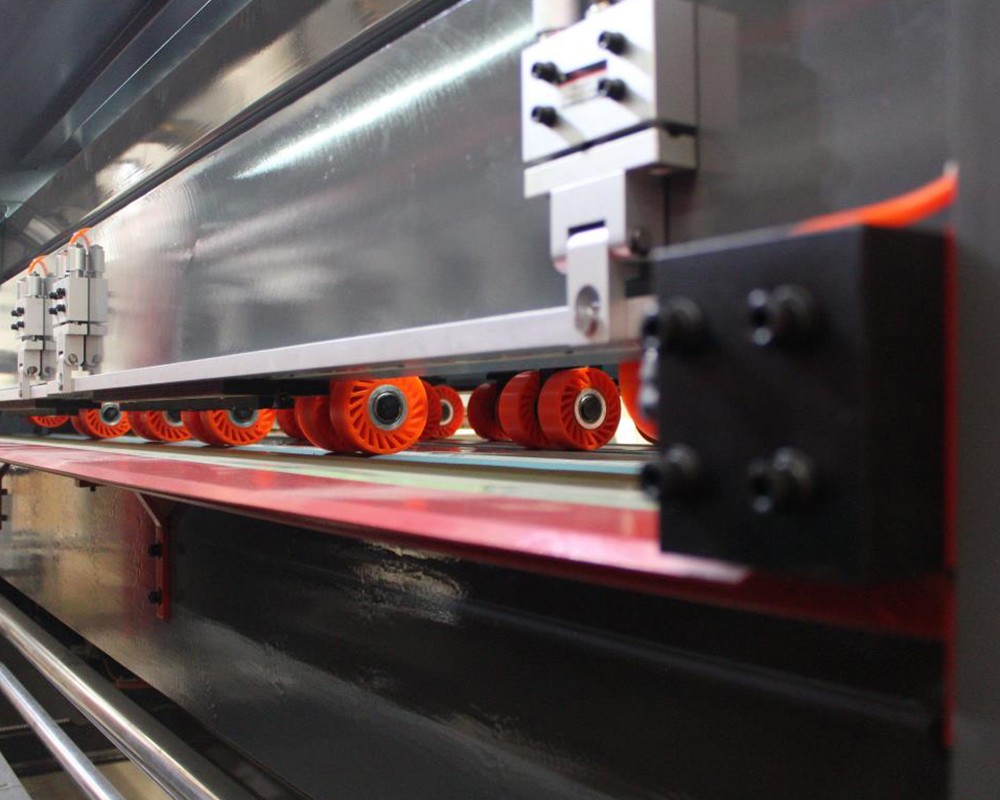

Corrugated Paper Box Machinery adopts Q235 thickened steel plate welding main frame, and all moving axes are hard chrome treated and high-precision linear guide rails, which can keep the equipment structure from deformation and jamming under high load and high-speed operation. Key components such as paper feeding rollers, pressure wheels, knife shafts, etc. are made of alloy steel and heat-treated to ensure that the equipment can still maintain stable operation under 24-hour continuous operation. The main motor adopts internationally renowned brands such as Siemens or Schneider, with low noise and extremely low failure rate. The whole line is equipped with overload protection, emergency stop button, and automatic lubrication system, which greatly improves the stability and service life of the equipment and supports continuous operation for at least 10 years.

④ Energy-saving and environmentally friendly design - reducing energy consumption and operating costs

While ensuring performance, Corrugated Paper Box Machinery adopts a number of energy-saving measures. For example, using servo drive instead of traditional motor can reduce energy consumption by about 25%; the printing unit is equipped with an environmentally friendly water-based ink system to reduce VOC emissions; the gluing station uses intelligent gluing technology to automatically adjust the amount of glue according to the shape of the carton to avoid waste. The average power of the whole machine is about 12~15kW when running, and the air pressure is about 0.5Mpa, and the energy consumption control is better than similar competing products. The green production concept not only helps companies improve their image, but also helps customers successfully pass environmental certification standards such as EU RoHS and REACH.

Corrugated Paper Box Machinery Application

① Electronic packaging factory in California, USA

In California, USA, a large electronic product packaging factory uses Corrugated Paper Box Machinery for the production of cartons for its export orders. The factory provides customized packaging for brands such as Google Nest and Fitbit, requiring cartons with beautiful appearance, strong structure and strong protection. Due to the diversity of order specifications, the factory pays special attention to the machine's fast order change and precise control capabilities. The Corrugated Paper Box Machinery can run at a speed of up to 250 sheets/minute, which significantly improves production efficiency. After application, customers reported that the defective rate dropped from 3% to less than 1%, saving more than 50,000 US dollars in material costs annually.

② Cold Chain Food Packaging Factory in Munich, Germany

A cold chain food packaging factory in Munich applies this equipment to the customized cartons for quick-frozen pizza and frozen seafood. The factory has high requirements for the thickness of the cardboard and needs to use 9~11mm corrugated cardboard to make a pressure-resistant structure. Traditional equipment cuts unevenly. Corrugated Paper Box Machinery uses a heavy pressure structure with an intelligent correction system, which can easily indent and shape even thick cardboard. The equipment is printed with special water-based ink to make food-grade packaging more environmentally friendly. After actual operation, the factory's production capacity has increased by 40%, and customer satisfaction has been significantly improved.

③ Cross-border e-commerce packaging center in Guangzhou, China

A cross-border e-commerce packaging center in Guangzhou, focusing on serving sellers on platforms such as Amazon, AliExpress, and Walmart, handles tens of thousands of order packaging needs every day. Due to the variability of orders and short delivery cycles, the center chose Corrugated Paper Box Machinery to build a flexible packaging system. The equipment supports one-click order change and can complete specification switching within 10 minutes, greatly alleviating delivery pressure. At the same time, the QR code and logistics information can be customized on the surface of the carton, and connected to the central ERP system to achieve information tracking and intelligent management.

④ Dubai luxury packaging workshop in the United Arab Emirates

Dubai's high-end packaging brand ArabLuxPack uses Corrugated Paper Box Machinery to produce exquisite cartons for high-end products such as perfumes, jewelry, and watches. For gift boxes with extremely high appearance requirements, the high-definition flexographic printing system of Corrugated Paper Box Machinery has become a key advantage. The equipment can support four-color printing, with clear graphics and rich colors, and can be combined with hot stamping, lamination and other processes to enhance the texture of luxury packaging. The brand currently customizes outer packaging for customers such as Chanel Middle East and Rolex UAE, and the equipment has played an important role in enhancing the brand image.