Automatic Cardboard Box Making Machine

Automatic Cardboard Box Making Machine adopts industrial-grade modular structure and PLC intelligent control system. The equipment frame is welded from high-strength carbon steel, equipped with human-machine interface color touch screen, intelligent warning light, closed safety protection cover and multi-channel cable management system. It is a fully automatic carton forming equipment designed for modern packaging industry, supporting the automatic feeding, creasing, slotting, corner cutting, folding, forming, bonding and other integrated operations of corrugated cardboard.

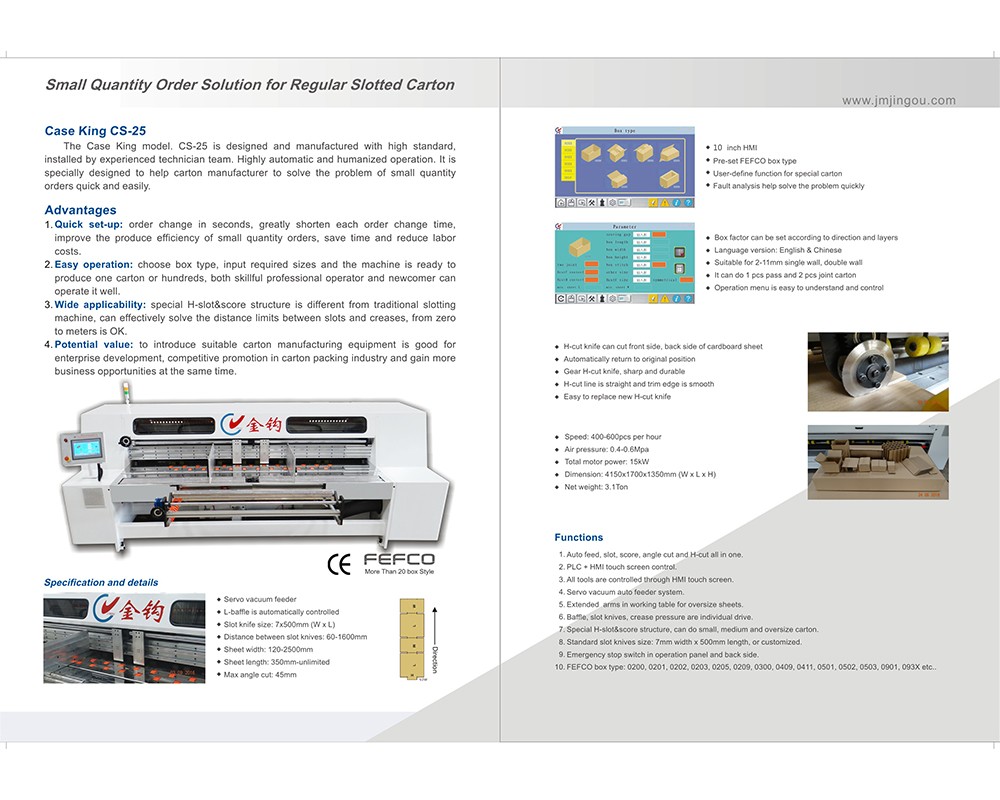

Automatic Cardboard Box Making Machine Features

① High degree of automation - one-stop carton manufacturing process integration

Automatic Cardboard Box Making Machine integrates functions such as automatic paper feeding, positioning, creasing, slotting, corner cutting, folding, gluing and sealing. It can complete the entire carton manufacturing process in one machine without manual transfer, greatly saving labor costs and production time. The system coordinates the control process through built-in sensors and PLC to ensure that each step is completed with high precision and the box size consistency is excellent. For the standard box type 0201, its molding cycle can be as short as 10 seconds and the maximum production capacity exceeds 1,000 boxes/hour, which is an ideal part of the automated packaging line. At the same time, it supports 24-hour continuous operation to ensure stable delivery of large order scenarios.

② Intelligent control system - accurate, visual and easy to operate

Automatic Cardboard Box Making Machine is equipped with a 7-inch or above industrial-grade color touch screen with a clear operation interface and supports bilingual switching between Chinese and English. Through the built-in industrial PLC and servo drive control system, the operator only needs to enter parameters such as the length, width and height of the carton, and the system can automatically complete the adjustment and positioning of the corresponding tools and components. Automatic Cardboard Box Making Machine supports the storage of hundreds of sets of product parameter templates, which is convenient for quick call of repeated orders. It also supports barcode/QR code recognition to achieve ERP system docking and remote collaborative scheduling. The whole machine has fault self-checking and intelligent shutdown functions to improve operation safety and reduce maintenance risks.

③ Diversified adaptability - Supporting a variety of carton structures and cardboard thicknesses

Automatic Cardboard Box Making Machine can not only manufacture conventional express boxes, moving boxes, and food packaging boxes, but also supports a variety of structural forms such as top and bottom cover boxes, window display boxes, bevel boxes, and special-shaped packaging boxes. It can support corrugated cardboard with a maximum width of 2500mm and a thickness of 11mm. The paper feeding unit can adjust the width of the cardboard channel to adapt to a variety of specifications of cardboard from single-layer E tiles to three-layer BC tiles. The tool system adopts a servo independent control structure, which can accurately control the cutting angle and indentation depth. It meets the needs of different applications such as electronics, food, medicine, and e-commerce customized packaging for diversified box sizes and structures, and truly realizes "one machine with multiple functions".

Automatic Cardboard Box Making Machine Application

① German e-commerce logistics warehousing center

In a large e-commerce logistics warehouse in Munich, Germany, this model of Automatic Cardboard Box Making Machine is deployed at the end of the automatic picking line. The Automatic Cardboard Box Making Machine is connected to the WMS warehouse management system to automatically generate matching cartons according to the SKU volume of each order, avoiding filling waste and increased transportation costs caused by oversized cartons. Only two people are needed to monitor the operation of the equipment in the storage area, and the maximum daily production capacity can reach 20,000 orders. This model effectively integrates automatic packaging, order sorting and box labeling, helping companies maintain high-speed and stable delivery efficiency in a high-frequency and changing order environment.

② US cold chain fresh food distribution base

In a large cold chain fresh food distribution center in California, the Automatic Cardboard Box Making Machine is used for the customized production of fresh food packaging boxes. Due to the size and shelf life of the food, each batch of orders requires the cartons to strictly match the volume to avoid the gap in the box affecting the cold preservation effect. By presetting multiple box templates, staff can quickly select and batch produce in the interface to connect to the on-site boxing process. The Automatic Cardboard Box Making Machine uses a moisture-resistant coating to adapt to the operation in a cold storage environment. It also uses automatic box gluing and detection functions to ensure that the carton edges are firmly sealed and leak-proof. It is a key process node for fresh food delivery packaging.

③ Multi-category order line of Japanese OEM factory

An OEM packaging factory in Tokyo that manufactures for multiple brands has a wide variety of products and large differences in carton sizes. It chose to introduce the Automatic Cardboard Box Making Machine to solve the problem of frequent mold changes and order switching. The Automatic Cardboard Box Making Machine supports box type switching within 1 minute and is suitable for a variety of special structures, such as tri-fold lids, vent boxes, and special-shaped slotted cartons, perfectly meeting its fast-paced, small-batch, and multi-batch mixed order needs. The system memory function can save each customer's customized parameters, improve the efficiency of re-order processing, greatly enhance the flexibility of production scheduling, improve delivery efficiency, and reduce box inventory.

④ French high-end wine packaging factory

A high-end wine exporter in the Bordeaux region of France uses the Automatic Cardboard Box Making Machine to provide customized outer packaging services for its glass bottle wines. The precise creasing and cutting capabilities of the Automatic Cardboard Box Making Machine ensure the compressive strength and aesthetics of the carton structure, and the customized envelope design enhances the product brand image. Wine cartons need to have good load-bearing and excellent shock resistance. The machine has a built-in pressure relief function and a double-track creasing device to effectively control the box deformation rate and ensure stability and safety during transportation. It is favored by many European wineries and boutique supermarket purchasing managers.

Previous: Cardboard Box Manufacturing Machine