Cardboard Box Manufacturing Machine

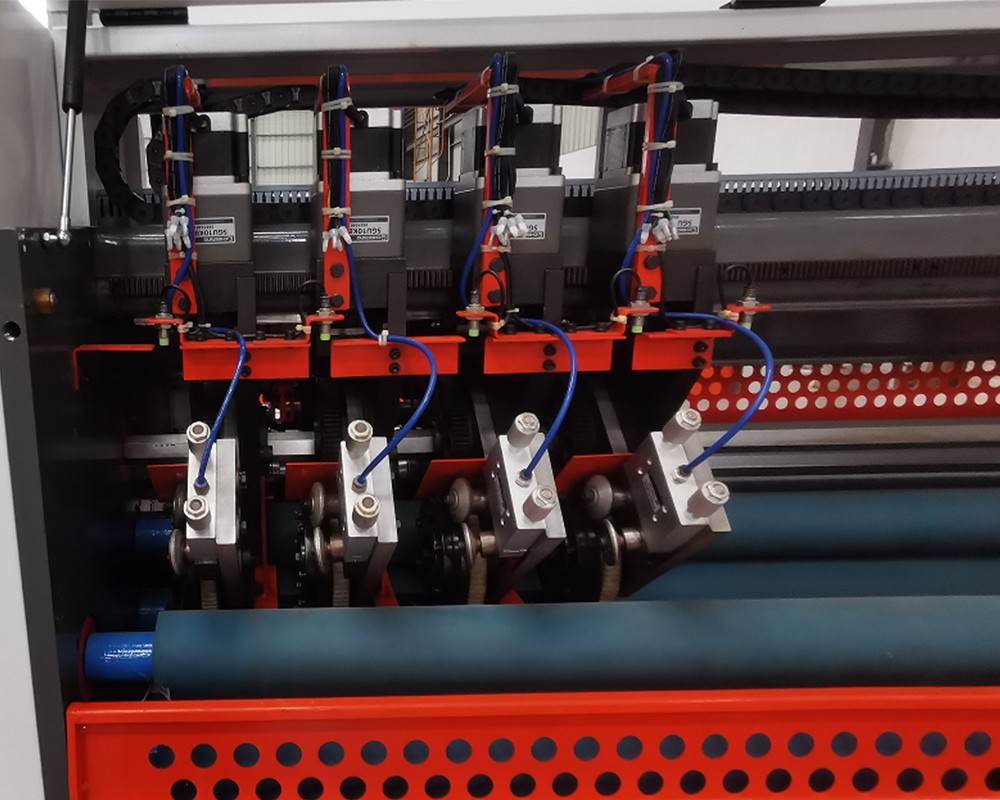

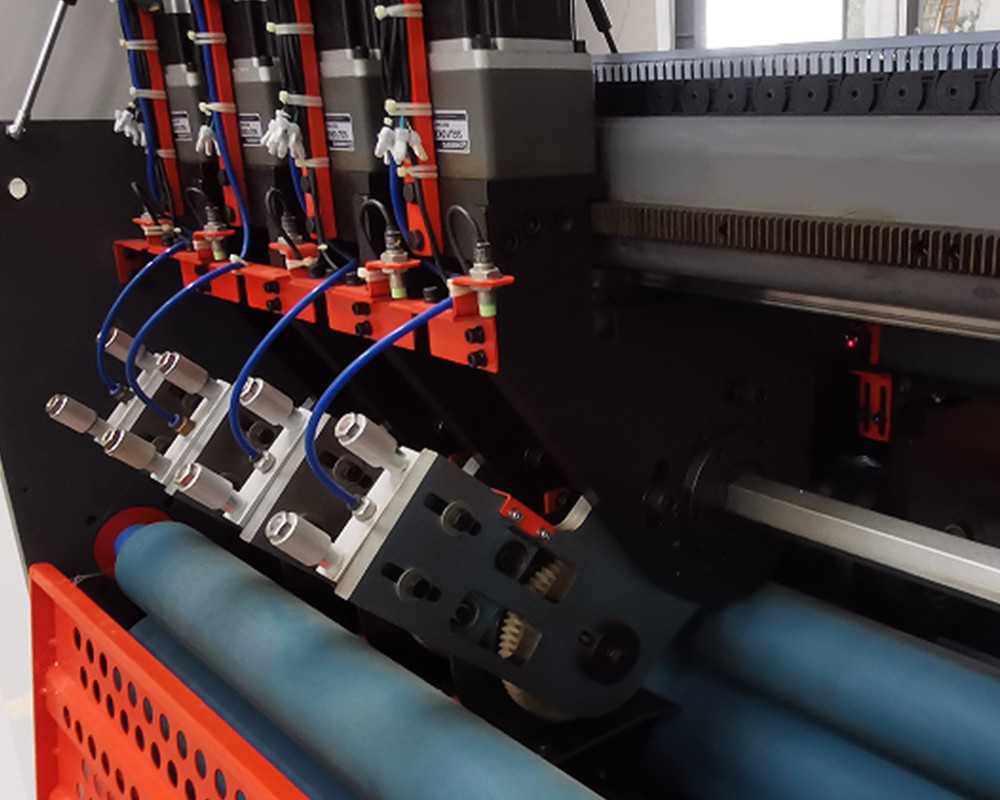

The Cardboard Box Manufacturing Machine adopts a high-strength industrial carbon steel frame structure, the shell is treated with high-temperature spraying, the main body is equipped with a color touch screen and an emergency stop button, all transmission parts are driven by a servo system, the front end is an automatic paper feeding system, the middle part is equipped with creasing, slotting, corner cutting and bending mechanisms, and the end is completed by gluing and sealing. It is an efficient box manufacturing equipment that integrates fully automated production, intelligent control systems and multi-functional cardboard processing capabilities. It is designed for packaging companies, logistics warehousing, e-commerce sorting centers and other application scenarios with large demand and many categories.

Cardboard Box Manufacturing Machine Features

① High-speed molding - achieving efficient production rhythm

The Cardboard Box Manufacturing Machine is equipped with an advanced PLC control system and multi-axis servo motors, with an hourly production capacity of up to 1,200 standard cartons, greatly improving the efficiency of traditional manual operations. The automatic paper feeding mechanism can continuously convey multiple sheets of cardboard, and through infrared detection and intelligent spacing systems, it ensures that each sheet of cardboard is still accurately positioned and jammed at high speeds. After the box type is set, the entire process does not require manual intervention, and the program automatically completes creasing, die-cutting, folding and gluing, truly realizing assembly line automation. In large-scale production enterprises, this type of high-speed forming Cardboard Box Manufacturing Machine can work continuously for 24 hours, has high-load operation stability, and is one of the core equipment for realizing modern factory automation.

② Intelligent control - support multi-language touch screen interaction

Cardboard Box Manufacturing Machine uses a 7 to 10-inch industrial-grade color touch screen operation interface, with built-in Chinese and English and other multi-language operating systems, which is easy for operators from different countries to get started. The intelligent program can save 100+ box templates. The operator only needs to enter the basic parameters such as the length, width, and height of the box body to automatically call the corresponding module to complete the structural adjustment. The system has a built-in parameter calibration module. When the thickness of the cardboard or the batch changes, it can intelligently prompt whether to adjust the tool pressure and adhesive parameters to reduce the dependence on manual experience. In addition, it also supports remote network maintenance and cloud management to assist buyers in completing the overall layout and deployment of intelligent factories.

③ Support for multiple carton styles - flexibly respond to diverse needs

Cardboard Box Manufacturing Machine has a modular and adjustable die-cutting system and slotting device, which supports one-click conversion of various structural styles such as 0201 standard express boxes, top and bottom cover boxes, special-shaped display boxes, tri-fold cover boxes, and bevel boxes. Through the servo-controlled angle positioning system, the accuracy of slotting and cutting can reach ±0.5mm, ensuring the accuracy of box splicing and loading strength. In addition, Cardboard Box Manufacturing Machine can also customize double-slot or no-slot box types according to user needs, and add functional modules such as punching and handle opening, which greatly enhances the diversification of carton manufacturing. It is particularly suitable for factories that provide customized packaging services for multiple SKUs and multiple industries.

Cardboard Box Manufacturing Machine Application

① Local third-party logistics warehouse in the United States

A large third-party logistics and warehousing company in Chicago uses Cardboard Box Manufacturing Machine as one of its core packaging processes, mainly serving daily orders from e-commerce and light industrial brands. By integrating with the warehouse WMS system, the Cardboard Box Manufacturing Machine can automatically select carton size templates according to real-time order content and match them for manufacturing, greatly reducing the cost of manual picking and storage of standard boxes. At the same time, the automated carton manufacturing function greatly improves the order response speed and packaging efficiency, helping customers achieve service goals such as next-day delivery and same-day delivery.

② British Agricultural Product Packaging Cooperative

In a fruit and vegetable planting cooperative in Yorkshire, UK, the Cardboard Box Manufacturing Machine is deployed in the fruit packaging and processing workshop to customize cardboard packaging boxes of different specifications. Due to the diversity of agricultural product sizes and weights, customers need to customize multiple batches and multiple models of cartons all year round. The flexible box conversion and thick cardboard compatibility of the Cardboard Box Manufacturing Machine perfectly meet this challenge. The machine's high-pressure crease and pressure-resistant gluing technology ensure that the fruit does not deform or fall apart during transportation, effectively improving the export quality of agricultural products.

③ UAE Electronic Product Assembly Factory

An electronic consumer product brand assembly factory in Dubai Industrial Zone introduced the Cardboard Box Manufacturing Machine for mass production of spare parts transportation cartons for electronic audio, smart devices, home controllers and other products. Because Cardboard Box Manufacturing Machine transportation requires high buffer protection strength, the precise indentation and reinforced viscose structure of the equipment help the carton improve its impact resistance. Through Cardboard Box Manufacturing Machine, order-driven production is realized, which effectively reduces a large number of carton inventory and waste costs, and helps enterprises transform from traditional warehousing mode to intelligent flexible manufacturing mode.

④ Australian Art Packaging Company

A packaging design company in Melbourne that provides customized packaging services for galleries and art exhibits uses this machine to quickly manufacture art transport cartons of various sizes. Customers often ask for personalized packaging tasks to be completed in a short time, and traditional manual methods cannot meet delivery requirements. The Cardboard Box Manufacturing Machine can quickly import structural drawings through design software, convert and output corresponding structural cartons with one click, greatly shortening the time from design to molding, while also ensuring high-precision molding and aesthetics, and has been widely praised by art brands.

Previous: Carton Box Cutting Machine