Carton Box Cutting Machine

Carton Box Cutting Machine is made of thickened carbon steel frame, the shell surface is treated with high-temperature spraying and rust prevention, equipped with fully enclosed protective cover and safety grating. It is a high-precision automatic cutting equipment, mainly used for efficient cutting and forming of various corrugated cardboard and carton materials.

Carton Box Cutting Machine Features

① High-precision cutting-±0.5mm repeat positioning accuracy

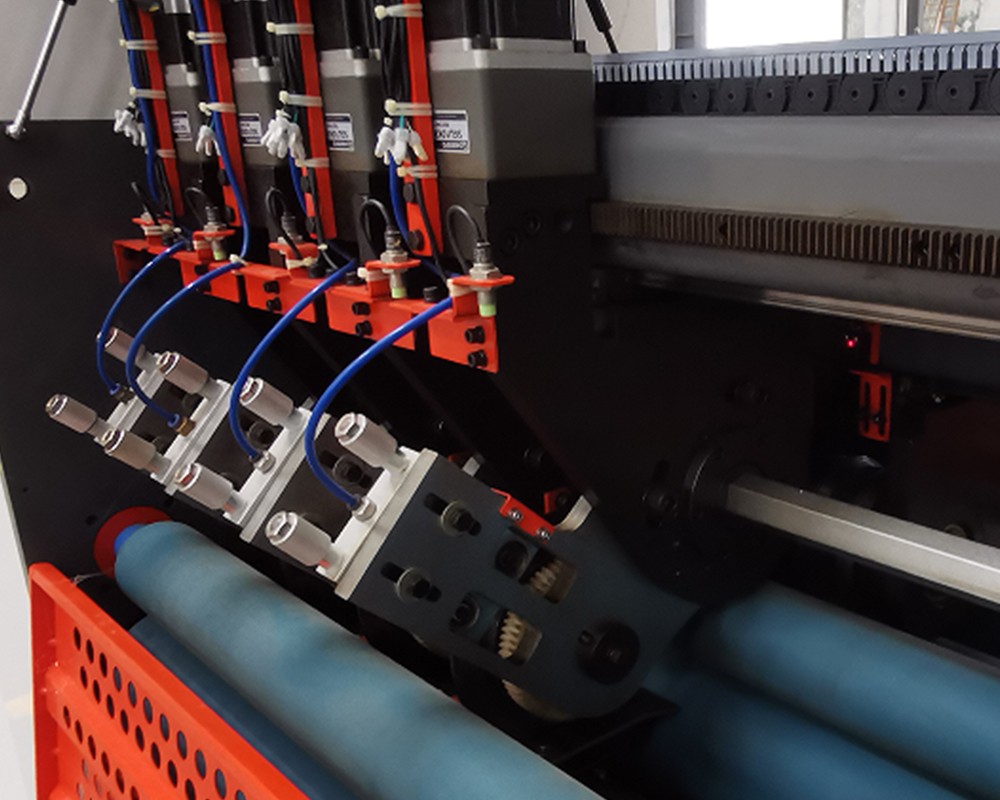

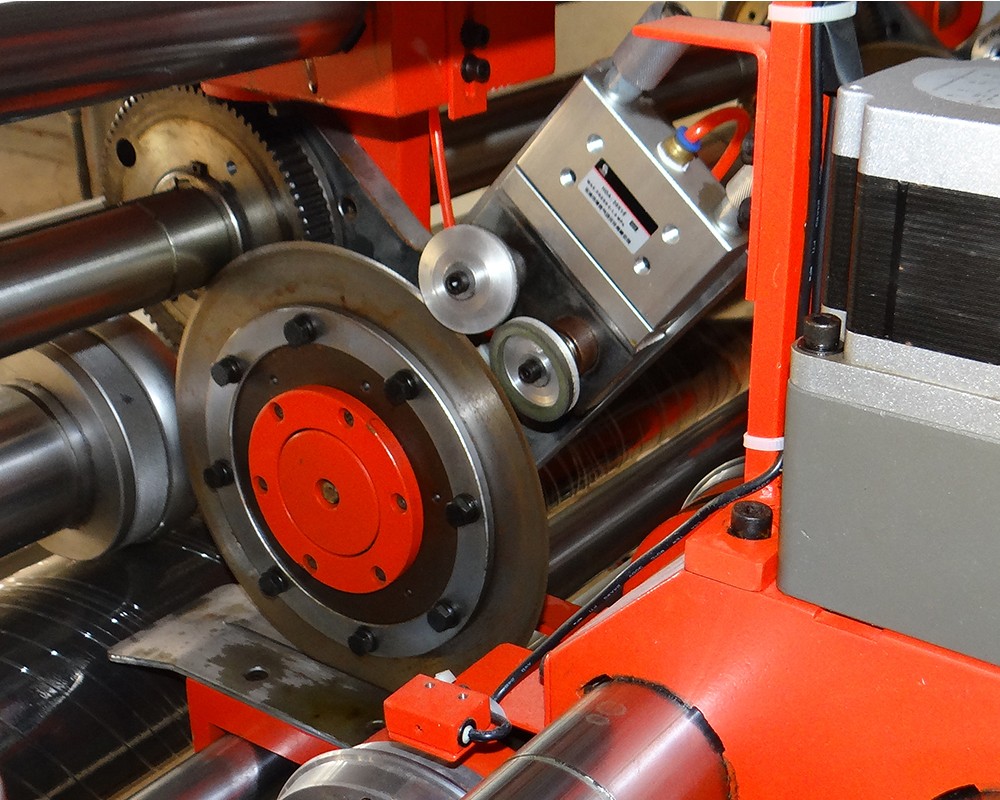

Carton Box Cutting Machine is equipped with a highly sensitive servo control system, with linear guide rails and synchronous belt drive, the cutting accuracy can reach ±0.5mm, and the repeat positioning error is extremely small. Carton Box Cutting Machine is suitable for a variety of carton design drawings, and can easily cope with complex curves, special-shaped structures and multi-angle cutting tasks, especially for customized packaging orders. The cutting head is made of alloy steel, which is wear-resistant and high-temperature resistant, ensuring that it remains sharp after long-term operation. Through the built-in CCD visual positioning system and cardboard correction mechanism, even slightly skewed or batch-error cardboard can automatically correct the path, effectively avoiding miscutting and waste generation, and significantly improving the cutting qualification rate and material utilization rate.

② Intelligent control system - multi-language interactive interface + remote diagnosis

Carton Box Cutting Machine adopts PLC intelligent program and touch control system, supports Chinese and English bilingual or even multi-language interface switching, which is convenient for customers from different countries to quickly master the operation process. The system has more than 100 commonly used carton templates built in. Users only need to enter the box type number and size parameters to automatically call the matching cutting path and depth settings, which greatly simplifies manual settings. The system also has a network interface and remote upgrade functions. When abnormal conditions occur, the manufacturer's technical team can remotely diagnose and maintain remotely to minimize downtime and ensure continuous production. At the same time, Carton Box Cutting Machine has an operation permission management function, which can set multi-level account permissions to prevent misoperation, improve management efficiency and factory digitalization.

③ Highly compatible material processing capabilities - adaptable to 2-11mm thickness cardboard

Carton Box Cutting Machine is compatible with E, B, C, BC, EB and other corrugated structure cardboards, with a cardboard thickness range of 2mm to 11mm, meeting the production needs of various light express boxes, large-size transport boxes, display boxes and other products. The independent pressure-adjusting knife holder and the high-frequency cutting path adjustment module can automatically adjust the knife pressure and feed speed according to the actual hardness of the cardboard, effectively avoiding problems such as uneven cutting and fluffing of the paper surface caused by different thickness or humidity changes. Its flexible tool system also supports fast tool change, maximizing production flexibility and the versatility of the Carton Box Cutting Machine, especially suitable for manufacturing scenarios with many SKUs and frequent order changes.

Carton Box Cutting Machine Application

① Large German e-commerce warehousing and sorting center

In a cross-border e-commerce distribution center in Leipzig, Germany, the Carton Box Cutting Machine is used as one of the core equipment for customizing cartons. The center handles more than 20,000 orders per day, and has extremely high requirements for carton size, style and efficiency. Traditional general standard boxes have a lot of space waste, and the Carton Box Cutting Machine can automatically cut the carton that best fits the product size based on the order system data, greatly reducing the use of fillers, improving packaging compactness, and reducing transportation costs. After the Carton Box Cutting Machine is integrated with the warehouse management system (WMS), it can read order requirements in real time, dynamically adjust the cutting size, realize "on-demand production, instant packaging", and optimize the entire distribution process.

② Australian home appliance brand packaging factory

In a well-known home appliance brand packaging factory in Sydney, the Carton Box Cutting Machine is mainly used for the customized production of outer packaging boxes for home appliances such as TVs, microwave ovens, and vacuum cleaners. Due to the different sizes of products, the buffering performance and compression resistance of the carton are required to be high. The Carton Box Cutting Machine can accurately cut according to different thicknesses and strengths of cardboard and cooperate with the pre-indentation device to achieve an enhanced corner structure, effectively improving the protection of the finished box. The factory supports the simultaneous production of different product lines through this equipment, shortens delivery time, and responds quickly to market demand. It is an important demonstration unit for the transformation of local smart manufacturing in Australia.

③ A cosmetics OEM packaging factory in Guangzhou, China

A Guangzhou company specializing in high-end cosmetics OEM has introduced this equipment for the production of various customized gift boxes, folding cartons and display boxes. Since cosmetic packaging requires beauty and structural complexity, the factory makes full use of the cutting equipment's special-shaped cutting and punching functions to customize the brand image structure. The window, socket, and handle of each gift box are all completed by the equipment in one piece, without the need for additional molds, which improves production flexibility. Especially during festival promotions, manufacturers can quickly switch to holiday version packaging templates, greatly shortening the launch cycle of new models and enhancing brand market sensitivity.

Previous: Corrugated Carton Making Machine