Small Cardboard Box Making Machine

Small Cardboard Box Making Machine uses carbon steel structure, equipped with industrial-grade slide rails and PLC intelligent control system, which can flexibly process single-layer corrugated cardboard such as E-tile, F-tile, B-tile, etc. It is a compact packaging equipment designed for small batches that integrates cutting, creasing, slotting and forming.

Small Cardboard Box Making Machine Features

1. Compact body structure, saving space

The size of the Small Cardboard Box Making Machine is about 1600mm × 1200mm × 1450mm, and the weight is controlled within 380kg. It is suitable for workplaces with limited space such as e-commerce packaging rooms, teaching laboratories or trial production workshops. The embedded electronic control system and folding feeder rack ensure that the operating area is compact and the layout is reasonable, which is convenient for users to flexibly arrange production lines.

2. Smart touch operation, simple and easy to learn

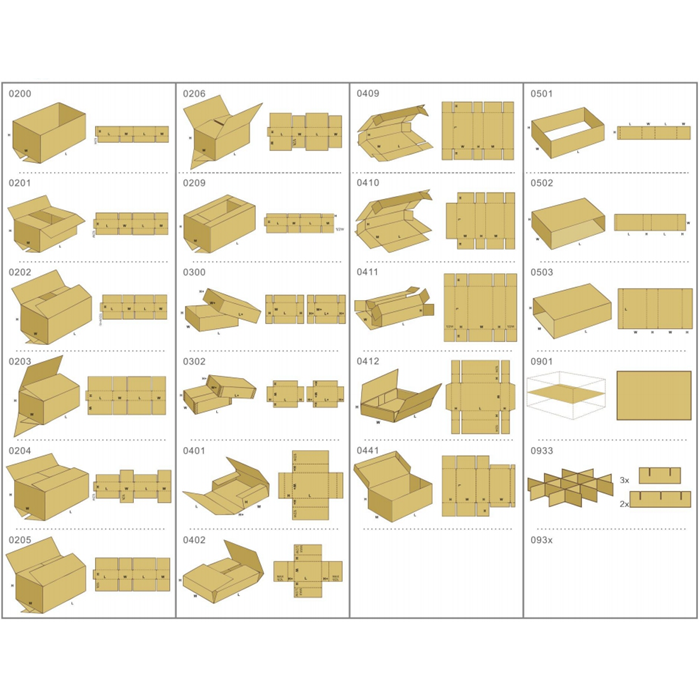

The Small Cardboard Box Making Machine is equipped with a 7-inch full-color LCD touch screen, and the Chinese and English operating system can quickly set parameters such as cutting size, creasing depth, box template, etc. There are 10 commonly used paper box style templates built in, and CAD drawings can be imported via USB or WIFI and called with one click. Ordinary employees can operate it proficiently after short-term training, which is suitable for small and medium-sized enterprises.

3. High-precision servo system to ensure molding accuracy

Small Cardboard Box Making Machine adopts Japanese Panasonic servo motor and ball screw linear guide system, with feeding accuracy controlled at ±0.5mm and cutting accuracy controlled at ±0.3mm. Even in the production of micro-sized gift boxes, it can ensure neat edges and smooth slots, effectively reducing the error rate of finished products.

4. Multi-corrugated paper compatible and widely adaptable

Small Cardboard Box Making Machine supports processing single-layer corrugated paperboard with a thickness of 1.5mm~5mm, including E-wafer, F-wafer, B-wafer, N-wafer and other micro-corrugated materials. It can flexibly switch between paper materials from different suppliers without changing the die. Some models also support cutting operations of some gray cardboard, honeycomb paper, and composite cardboard.

5. Low energy consumption operation, suitable for long-term work

The power of the whole machine is only 1.8kW, and the power consumption is low in normal use. It supports 220V single-phase power supply mode, which is suitable for small and medium-sized factories, e-commerce processing stations, and school laboratories. There is an intelligent standby mode inside, which automatically switches to a low power consumption state after 10 minutes of shutdown to extend the electrical life.

6. Fast changeover capability, adapting to customized production

No traditional molds are required, and the product style can be switched by changing the size parameters or changing the drawings. The average changeover time is less than 2 minutes, which is particularly suitable for multi-SKU, small batch orders, such as holiday gift boxes, e-commerce express boxes, and customized cultural and creative packaging boxes.

Small Cardboard Box Making Machine Application

1. Customized gift box processing factory in Los Angeles, USA

Small Cardboard Box Making Machine is used by L.A Custom Gifts Packaging Company in the United States to customize holiday gift boxes, birthday gift boxes and souvenir boxes. It handles more than 50 orders of different sizes every day to meet the rapid switching of multiple SKUs and multiple brands. The machine's mold-free operation saves it a lot of initial investment.

2. Bologna Cultural and Creative Product Workshop, Italy

ArtBox Bologna, Italy, uses Small Cardboard Box Making Machine to customize personalized packaging for its books, cards and art souvenirs. The small model is easy to deploy in the handmade studio, allowing customers to select the size and pattern, and cut immediately, which enhances the brand added value and customer experience.

3. Cross-border e-commerce packaging room in Shenzhen, China

An Amazon seller deployed Small Cardboard Box Making Machine in the Longgang Operation Center in Shenzhen to provide instant carton customization for orders of thousands of pieces per day, saving inventory and standard carton waste. Combined with the barcode printing system, one box for one product, accurately matching the transportation space.

4. Training Center of the Cologne Packaging Design Academy in Germany

Small Cardboard Box Making Machine is used in the packaging design professional training room of the Cologne University of Applied Sciences for students to practice box structure design and molding practice. Teachers can send drawings to the device terminal via WIFI, and students can complete the entire process of design → cutting → molding within 30 minutes, improving teaching efficiency.

5. Coffee Packaging Studio in Melbourne, Australia

Melbourne BrewCraft Studio is used to make local boutique coffee bean packaging boxes, supporting integrated cutting of cardboard after printing, with small order quantities and fast updates. The product structure is mostly a small-sized hand-held box with a top and bottom cover, and the equipment accuracy and efficiency meet its high-frequency replacement needs.

6. External packaging production of jewelry pop-up stores in Dubai, UAE

Small Cardboard Box Making Machine cooperates with mobile display booths to provide temporary customized packaging boxes for pop-up events. The Dubai GEMZONE jewelry exhibition once deployed Small Cardboard Box Making Machine in the back area of the venue to produce cardboard boxes with LOGO hot stamping on the spot to enhance customer brand interaction.

Additional support services:

Support customized colors, LOGO printing, voltage specifications (110V/220V)

Provide online installation videos and operation manuals

Can provide CE, ROHS certification, certificate of origin, Form A/F and other export information

1-year warranty, lifetime technical support, support global remote assistance

Support customized matching folding devices, gluing devices, label pasting units

Previous: Automatic Carton Making Machine