Automatic Carton Making Machine

Automatic Carton Making Machine is an intelligent device that automatically processes corrugated cardboard raw materials into finished cartons. It is suitable for a one-stop carton production process from cardboard feeding, cutting, creasing, die-cutting, slotting, folding, sealing to stacking.

Automatic Carton Making Machine Features

1. Full process automation improves overall production line efficiency

Automatic Carton Making Machine supports fully automatic operation from corrugated cardboard feeding to forming and unpacking, without manual intervention in any intermediate process. The system integrates servo-driven feeding + modular die-cutting + intelligent changeover control system, with the fastest running speed of 25~35 boxes/minute, truly realizing batch, high-frequency, multi-specification automated processing, reducing labor input by more than 70%.

2. Intelligent identification and switching orders to adapt to diverse packaging needs

Automatic Carton Making Machine is equipped with a multi-work order intelligent memory system, which can preset up to 1,000 work order parameters of different carton sizes/structures, and quickly switch orders through barcode scanning or screen input. It supports real-time fine-tuning of indentation, cutting, and folding depth, and the average changeover time is as low as 2 minutes, which perfectly adapts to the multi-SKU packaging needs of e-commerce and brand owners.

3. High-precision die-cutting unit to ensure the quality of carton forming

Automatic Carton Making Machine uses imported die-cutting knife mold + automatic pressure adjustment device, and the die-cutting accuracy is controlled within ±0.5mm. It can handle a variety of cardboard structures such as E tiles, B tiles, C tiles, double-layer AB tiles, etc. Whether it is conventional slotting, handle opening, special-shaped windows or internal support positioning, it can quickly die-cut and form to ensure that the carton is assembled tightly and does not crack.

4. Intelligent operation interface, intuitive and simple control

Automatic Carton Making Machine is equipped with a 10.1-inch color HMI touch screen, the interface is clear and intuitive, supports multi-language switching (including Chinese, English, Spanish, Arabic, etc.), and has automatic alarm, maintenance reminder, consumables monitoring, production statistics and other functions. Built-in remote diagnosis module supports technical support and program upgrades through the network.

5. Low-noise operation, energy-saving and environmentally friendly

Automatic Carton Making Machine adopts imported silent chain drive + shockproof structure design, with an operating noise of less than 68 decibels. It can be deployed directly next to the office without the need for an independent soundproof room. At the same time, the power consumption of the whole machine is optimized, and the average operating power is controlled at 3.5~4.0kW, which saves more than 25% energy compared with the traditional carton production method.

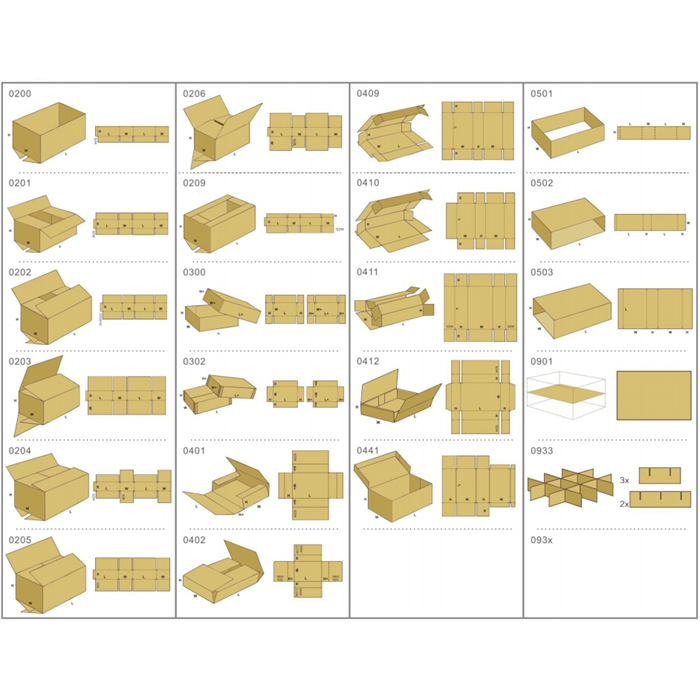

6. Strong compatibility, supporting the production of multiple types of carton structures

Automatic Carton Making Machine is suitable for the processing of various structures such as RSC standard carton, FOL double-cover carton, Wrap-around paper box, top and bottom cover gift box, special-shaped display carton, etc., without the need to replace hard molds, and the modification is fast, which is suitable for high-frequency and diversified shipping packaging scenarios.

Automatic Carton Making Machine Application

1. Tokyo e-commerce express packaging center in Japan

The Tokyo sorting warehouse of Rakuten, a large cross-border e-commerce platform in Japan, introduced this automatic carton making machine for the self-production of shipping boxes with an average of 40,000 orders per day. Combined with the WMS system and barcode recognition device, the Automatic Carton Making Machine can automatically switch carton sizes according to orders and deliver cartons on demand, greatly reducing inventory and standard carton waste.

2. Packaging workshop of a food processing company in Hanover, Germany

The SCHULZ Frozen Food Group in Hanover purchased the Automatic Carton Making Machine for daily refrigerated/frozen food packaging box production. The machine is equipped with a low-temperature resistant hot melt adhesive system for sealing, which can be operated around the clock. It effectively supports food safety standards and improves the cleanliness and efficiency of corporate packaging.

3. Industrial electrical appliance manufacturing plant in Toronto, Canada

Toronto ELECTRAX Industrial Automation Company uses the Automatic Carton Making Machine for on-site customization of high-protection electronic component transport cartons. Due to the variety of order sizes, the original use of standard cartons caused a lot of space waste. By making precise-sized cartons by the Automatic Carton Making Machine, more than 20% of transportation costs are saved each year.

4. Automated packaging line of home appliance factory in Riyadh, Saudi Arabia

AL-ZAMAR home appliance manufacturing plant deploys this carton making equipment to the terminal of its automated packaging line, which is used for the immediate production of home appliance cartons such as televisions and washing machines. Automatic Carton Making Machine is compatible with large AB double-tile structure cardboard and supports pressurized sealing system to ensure that the compressive strength of the formed cartons meets the export sea transportation standards.

5. Customized packaging materials for clothing brand factory in Cape Town, South Africa

At LEON STYLE Clothing Group in Cape Town, Automatic Carton Making Machine is used for its online personalized clothing order supporting packaging. Combined with RFID label pasting and QR code scanning functions to achieve "one box, one code", it significantly improves customer experience and becomes the core link of the brand's supply chain upgrade.

6. Compliance packaging workshop of pharmaceutical companies in Mumbai, India

JMD PHARMA Pharmaceutical Factory in Mumbai uses Automatic Carton Making Machine for automatic forming and production of pharmaceutical transport packaging. Automatic Carton Making Machine complies with the Indian pharmaceutical packaging GMP specifications, and combines with the visual inspection system to automatically check the formed cartons, effectively reducing the error rate and improving packaging efficiency and stability.

Additional service support content:

Optional visual recognition system, robot packing interface, automatic stacking device

Provide global on-site debugging and remote online support

Comes with 3D CAD installation diagram, power configuration diagram, electrical schematic diagram

Can provide CE, UL, SASO, COC and other export certifications

Support voltage customization: 220V/380V/415V; 50Hz/60Hz

Previous: Cardboard Box Cutting Machine