Cardboard Maker Machine

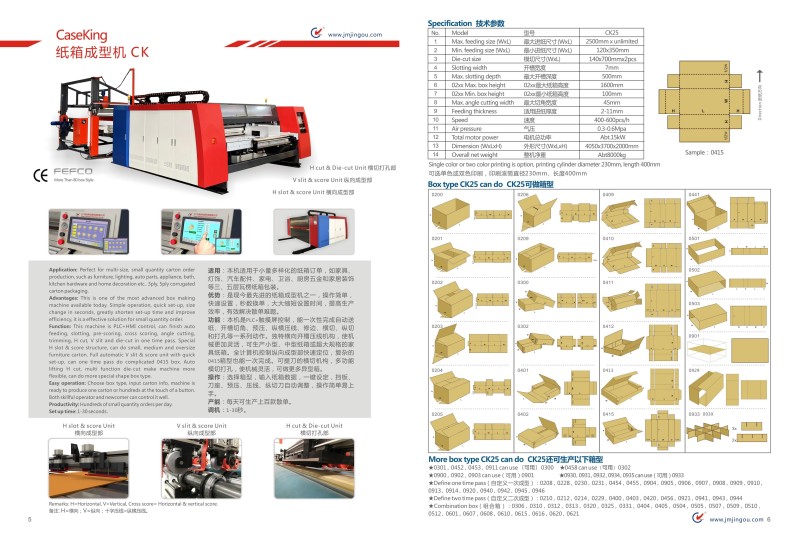

Cardboard Maker Machine is equipped with a high-definition touch screen, automatic feeding device, die cutting system and creasing unit. It is a corrugated cardboard forming equipment that integrates intelligent control and high-precision mechanical systems. It is suitable for mass production of customized cartons of different sizes and types.

Cardboard Maker Machine Features

High-precision control system

Cardboard Maker Machine is equipped with a multi-axis servo motor control system with a cutting accuracy of up to ±0.5mm, ensuring the consistency of cardboard forming dimensions and adapting to customized packaging needs. It adopts PLC programming + touch screen operation interface, which is more intuitive to operate and supports multi-language switching, suitable for users in the global market.

Multi-function integrated design

Cardboard Maker Machine integrates multiple functions such as slotting, cutting, creasing, folding, etc., and can complete the entire carton forming process at one time. The thickness range of the adapted cardboard is 2mm to 10mm, which effectively reduces the secondary processing links and improves production efficiency.

Flexible size adjustment capability

Cardboard Maker Machine supports fast change of carton size, with a minimum cutting width of 100mm and a maximum width of 2500mm, meeting different size requirements from small electronic product packaging to large logistics boxes, and is particularly suitable for small and medium-sized batch diversified orders.

High-speed continuous operation performance

The maximum operating speed can reach 200 sheets/hour, which is suitable for medium and high-intensity production lines, with 24-hour stable operation capability, and is equipped with automatic counting and paper stacking system to optimize overall delivery efficiency.

Energy-saving and environmentally friendly operation mode

Cardboard Maker Machine is equipped with energy-saving variable frequency drive and automatic standby function to reduce the energy consumption of the equipment under no-load state. The energy consumption of the whole machine is only 3.5kW/h, which is much lower than that of traditional cardboard cutting equipment, and supports green factory certification requirements.

E-commerce warehousing and logistics center

Cardboard Maker Machine is widely used in self-operated warehousing centers of e-commerce platforms such as Amazon and eBay for customized carton packaging. Its fast changeover and automatic cutting functions can quickly respond to the packaging needs of diversified SKUs and improve packaging speed and accuracy.

Cardboard Maker Machine Application

Home appliance brand production workshop

Serving home appliance manufacturers such as Haier and Hisense, it is used to customize high-strength cartons according to the sizes of products such as different models of TVs and refrigerators to ensure the stable protection and uniform appearance of the products during transportation.

Customized packaging companies

Widely deployed in professional customized packaging companies such as Packlane and Packhelp, it supports the efficient production of small batches and multi-size orders, and is especially suitable for the flexible manufacturing of creative packaging such as brand customized cartons and gift boxes.

Food processing and distribution center

Cardboard Maker Machine is used by food brands such as Nestlé and Unilever to cut and manufacture cold chain and room temperature food transport boxes, ensuring the sealing and stacking strength of food packaging, while reducing the pressure on outer packaging inventory.

Printing and packaging industrial park

As one of the important intelligent equipment in the printing and packaging industrial clusters in Foshan, Guangdong, China and Wenzhou, Zhejiang, Cardboard Maker Machine provides flexible production capabilities for small and medium-sized packaging and printing factories, improving unit production capacity and order-taking capabilities.

Previous: Cardboard Manufacturing Machine